Respiratory Protection Equipment (RPE) is essential gear for protecting you from inhaling hazardous substances. In this blog, we’ll explore the important role of RPE, whether you are dealing with airborne contaminants like asbestos, fumes, or dust, RPE is an essential protective equipment (PPE) that makes sure you can breathe safely. Join us as we deep dive into the different types of RPE, their applications, and how they can protect you from potential health risks.

Before you even get started with RPE, make sure you have other practical control measures in place first; such as local exhaust ventilation or direct dust-extracted tools with a vacuum catchment to get rid of the majority of contaminants in the air. You should also be keeping an eye on your team’s health and workplace conditions to ensure that, over time, they aren’t being made sick or getting injured by their work.

Remember, there is no such thing as a healthy dust, even if you are outside!

We’ve gone ahead and put together a quick guide of factors to consider when providing your workers with RPE.

Types of RPE

Dust masks are basically the bottom of the list of ways to protect yourself, we would not recommend using these as they are mostly ineffective at creating a seal between you and the contaminants.

Respirators use replaceable filters to remove contaminants to clean the air for the wearer. They come in half-face and full-face versions. The cartridge filters are specific to certain types of contaminants, ask your manufacturer exactly which cartridge you should be using for the respirator you have and the contaminants you will be facing.

Remember if you have stubble or any facial hair you may not be getting the seal and the protection you think you are! So if you love your beard as much as your lungs read on to find out what you can do.

Powered air purifying respirators (PAPRs)

Are made up of headgear and fan assembly that take contaminated air, filters it, and then delivers the clean air to the user. These are also known as positive pressure systems. These not only keep you nice and cool, but offer the highest protection there is for people who have facial hair. Something to note with these is that the visors and headset can be impact rated if you need it, and don’t fog up because of the airflow

Supplied air respirators

Provide a supply of clean air to the wearer from a source such as an air compressor or cylinder. It’s important to note that the air supply needs to be checked regularly to make sure that it is safe to use – just think about what you see coming out of your air compressor when you release the valve under the air tank! The user must also be trained in how to use the system. If using these RPE’s you need to notify WorkSafe.

Using respiratory protection equipment

It’s important for your workers to visually check their RPE for signs of damage before each use to identify any issues, including whether it needs to be cleaned or decontaminated.

Make sure your team keep their RPE on while working in the hazardous area. Removing it for even a short period of time is a risk to their health.

Did you know that they come in different sizes? One size does not fit all!

If your workers are using RPE then make sure they are fit tested, this way you will know who needs what size, otherwise it may not work and give the protection your workers need.

The manufacturer of the RPE can tell you who can do this testing.

There are two checks which you need to do each time you use and RPE:

1 – check for damage visually to the sealing surfaces and straps

2 – check the valves are functioning correctly like WorkSafe images below

Image Source: Worksafe New Zealand

Keep in mind that if your worker’s safety glasses fog up while they are wearing a half-face respirator, this is a sign that there is a leak at the top of the respirator which means they are not getting full protection.

Life Shavers: Shaving your beard could save your life

When your workers are wearing respiratory protective equipment at work, they must be clean shaven to ensure it is forming a seal and protecting them from breathing in hazardous materials. Even a small amount of stubble can prevent RPE from sealing correctly which means your workers will still be inhaling harmful materials which may cause health concerns. A clean shave goes hand in hand with the correct RPE for the job.

It’s your legal responsibility to monitor your workers’ health. Make sure that you are completing regular Site Reviews on the HazardCo App, as this will help you to identify potential hazards and put effective plans in place. Your HazardCo Support Team is available throughout the day to guide you through this – call 0800 555 339 to talk it over.

Image Source: Worksafe

Exposure to silica dust has been spotlighted as one of the major risks to workers in the construction industry. According to 1 NEWS, more than 100 enforcement actions have been taken against Kiwi businesses since alarms were raised in Australia, where there have been several deaths from silica dust.

What is silica dust?

Great question! Silica dust (crystalline silica) is found in some stone, rock, sand, gravel, and clay. You’ll mostly come across it in the following products:

- Bricks

- Engineered stone

- Tiles

- Concrete

- Some plastic material

When these materials are worked on, a fine dust is released known as respirable crystalline silica or silica dust. And it’s this dust that is harmful when inhaled into your lungs.

How can workers be exposed to silica dust?

You may be exposed to silica dust if your work involves:

- Construction

- Kitchen benchtop manufacturing, finishing and fitting

- Abrasive blasting

- Manufacturing of concrete, bricks and tiles

- Monumental masonry work

- Concrete drilling, cutting, grinding, fettling, mixing, handling, dry shoveling, tunneling

- Quarrying and roading

- Foundries

Are there significant health risks?

Yes, and they can be serious if the right precautions aren’t taken. Silica dust is 100 times smaller than a grain of sand, you can be breathing it in without even knowing it.

Workers may develop a series of lung diseases from breathing in silica dust, including silicosis, lung cancer, and chronic obstructive pulmonary disease. There is also some evidence that exposure to the dust may cause kidney disease.

What can be put in place on-site to mitigate the risks?

To follow health and safety laws, businesses should eliminate or minimise exposure to hazards by controlling the risks. For silica dust, this can be done in many ways:

Isolate work areas: Use physical barriers or computer numerical control (CNC) machines.

Look for dust control features: When buying equipment ensure dust-generating equipment has a dust collection system with a filtered air supply.

Use a H-class vacuum cleaner: Workers should not be using household vacuums to remove dust.

Set up exclusion zones: Mark the boundaries of work areas where dust is created. The signs should warn workers and specify the PPE to be used.

Personal Protective Equipment (PPE): PPE should not be the first or only control measure you consider but should be used. Seek expert advice when choosing it and consult with the worker who will be using it.

On-tool extraction: Use Local Exhaust Ventilation (LEV) that fits directly onto the hand-held machines. This is one of the most effective ways of controlling dust.

Water suppression: To be used when LEV is not suitable. Water should be used through non-electric tools to wet dust down at the point of dust generation. Also, make sure equipment and work areas are cleaned regularly with water.

Respiratory (breathing) protection: The type of respirator you choose will depend on the job and the levels of toxicity. Always choose a respirator that fully protects the worker and carry out fit testing so it is sealed tightly against the face.

Exposure and health monitoring: Provide health monitoring for all your workers who may be exposed to silica dust. You can engage with an occupational health practitioner at Habit Health – HazardCo customers even get a special discount.

Training: Health and safety starts with educating your workers. Provide them with information, training, and instruction on the control measures and the potential health impacts.

Remember employers are required to ensure the health and safety of their workers and others at their workplace, and have a duty to control the risks associated with the job.

At HazardCo, we’re all about education and equipping workers with the knowledge they need to get home safe at the end of the day. Educating everyone on-site about the danger and what we can do to reduce them creates a healthier worksite for everyone.

If you have any questions or want to know more about how to protect your team, get in touch today.

The workplace hazards that create risks of harm to psychological (mental) health are known as psychosocial hazards. These hazards, when excessive or prolonged, can cause serious harm. It can have a significant impact on workers, their families and business.

Mental health problems are common, with nearly one in two New Zealanders likely to meet the criteria for a mental illness at some time in their lives. Workplaces that prioritise mental health have better engagement, reduced absenteeism and higher productivity, while people have improved wellbeing and greater morale.

Psychosocial hazards can come from:

- Work relationships and interactions, including bullying, harassment, discrimination, aggression and violence

- The way the work or job is designed, organised and managed

- The equipment, working environment or requirements to undertake duties

What are some of the work-related factors that affect a mentally healthy work site?

- Work-related violence and aggression

- Workplace bullying

- Poor support

- Lack of recognition and reward

- Low role clarity

- Poor organisational justice

- Remote and isolated work

Whose responsibility is it to manage psychosocial hazards?

Workplaces have a legal responsibility to manage risks to mental health and wellbeing just like they do any other health and safety risk.

Knowing where to start can feel overwhelming but getting started doesn’t have to be. Take action to improve the mental health of your team today.

Tips to help build and maintain a mentally healthy work site:

Create a more positive and supportive work site.

-

- Develop an action plan in consultation with your workers about what you can do together.

- Check-in on your workers regularly. Start a genuine conversation. Ask your worker how they are going, and listen.

- Encourage respectful behaviour and communication.

- Walk the talk and lead by example. Supervisors demonstrate their commitment by being supportive and positive on site.

- Show your commitment by supporting mental health organisations and getting involved in awareness events.

- Reinforce the good behaviours regularly and address bad behaviours as they appear.

- Commit to zero tolerance for bullying, discrimination and violence/aggression.

- Encourage and support employees to bring up concerns when they notice unacceptable behaviours.

Establish awareness and support for workers experiencing mental health issues.

-

- Consistently raise awareness about mental health and well-being by having discussions such as 1:1 chats and tool box talks.

- Share information with your workers on mental health and how to seek help to help break the stigma. Posters, emails, and discussions can all be used.

- Encourage staff with mental health conditions to seek treatment and support early.

- Support staff with mental health conditions to stay at or return to work.

Celebrate workers and their efforts.

-

- Praise employees and give regular positive feedback for good work.

- Celebrate team success. A morning tea / BBQ is also great for team bonding.

Take steps to improve role clarity and job satisfaction

-

- Monitor and manage workloads regularly and increase input in how workers do their work.

- Have ongoing and regular conversations with employees about their performance and behaviour.

- Make sure your employees are clear about their roles. Position description, regular 1:1 catchups and reviews.

- Offer opportunities for learning, problem-solving and personal development.

- Support learning – provide opportunities for workers to learn and sharpen their skills, and set interesting challenges.

If you have challenges on your work site related to psychosocial hazards, give us a call for advice. As a HazardCo member you can have a chat with the experienced health and safety Advisory Team for no extra cost.

Lithium batteries are common in everyday life and on the worksite, their lightweight, long life, interchangeability and quick charge benefits mean that they are now used in everything from laptops to power tools to EVs. But did you know that they pose a significant risk and need to be a part of your health and safety plan?

What’s the risk?

Lithium batteries of all sizes have the potential to overheat and catch fire. The fire is hotter, harder to put out and the smoke from these fires is incredibly toxic. Lithium batteries generally overheat if they get wet, damaged or are used with incorrect charging equipment.

Damaged batteries can explode at any time giving off flames that burn anywhere between 500 and 1000 degrees celsius. These fires are very difficult to extinguish as both water and CO2 will only suppress the fire, not extinguish it. Even if the fire has been suppressed it can still ignite again if the battery still contains energy to burn. Lithium batteries are also prone to thermal runaway, which is where one small fault can spread quickly through the battery causing a rapid increase in temperature and potential explosion.

Because of this, lithium batteries need to be properly cared for according to the manufacturer’s instructions to minimise the risk, aside from that, you need a plan in place in case of a fire.

Hot tip: The bigger the battery the bigger the risk of fire and explosion because of the increase in stored energy being released, think energy in = energy out almost instantly so take extra care with larger battery packs – like the ones in your hand held power tools.

Ways to minimise the risk

- Storage: Keep lithium batteries away from spaces where a fire could ignite other things and spread easily. Also, keep them away from extreme temperatures and moisture.

- Charging:

- Always use the correct charger for the battery and do not over charge. Incompatible chargers lead to overcharging and overheating increasing the risk of fire.

- Do not leave batteries charging overnight or unattended. Noise and smoke are early warning signs.

- Consider using a smart charger that monitors battery status and can disconnect power if there is a fault.

- Remote disconnection: Provide easily accessible means for remote disconnection of the battery, think about if you would need to move past it to switch it off at the source if it went up.

- Enhanced fire safety measures: Put in place fire-resistant measures near charging sites. For example; Smoke alarms and fire extinguishers. Wherever possible charge in a cool dry place that lessens the chance of a fire getting into a structure.

- Monitor: Always check equipment for damage during and after use. Damage could include signs of being dropped, crushed or punctured.

- Emergency preparedness & PPE: Develop emergency response plans specific to lithium battery fires, including clear evacuation instructions. Provide clear training on the dangers, insulated tools and appropriate personal protective equipment (PPE) such as insulated gloves for employees involved in any equipment/battery maintenance, or better yet, give it to a professional to get it checked.

Safe lithium battery disposal

Never dispose of Lithium batteries in general rubbish as it can result in a fire in your bin or on the way to a transfer station, creating a risk to those transporting them. The manufacturer should be able to advise safe disposal or check out your local battery recycling centre.

Lithium batteries are going to continue playing a crucial role in our workplaces and lifestyles, so it’s necessary to recognize the potential hazards associated with them. By having awareness of these risks and good practices, we can work together to reduce the potential dangers, resulting in safer working environments where Lithium batteries are used.

If you have any questions, give the Hazardco team a call today!

Making sure your scaffolding is safe and ready for action is key. Here are the times you’ve got to give it a good once over:

- After Installation: Right after it’s set up.

- Every 7 Days: Yep, regular check-ups like clockwork.

- After Tweaks: Any time you make changes, give it a good once-over.

- Post-Storm or Shake-Up: If mother nature throws a fit, give it a look.

- Daily Check Before Use: A quick safety scan before diving in each day.

All scaffolds must be checked by a competent person before handover and scaffolds taller than 5m must be erected and inspected by someone who holds the appropriate Certificate of Competence (COC). Handover checks involve tagging the scaffolding. No matter the height, all scaffolding must have a tag clearly displaying important safety information at access points. The tag should include the following:

- Safety Status: Whether it is safe or unsafe to use.

- Contact details: The name and contact phone number of the person who erected it

- Purpose: What the scaffold is being used for

- Weight Limits: The weight loadings of the scaffold

- Platform limits: The maximum number of platforms or bays that may be loaded

- Limits of Use: Any limitations on the use of the scaffold

- Records: A record of each inspection including who inspected or altered the scaffold and when it was done.

If there’s no tag, do not use it! Get in touch with your scaffold installer to sort it out and get it tagged.

Before starting each day, a pre-start check should be done. This can be done by a competent scaffold user using the HazardCo scaffolding pre-start checklist available from the Hazardco HUB.

Every week a certified scaffolder (if over 5m) or competent person (under 5m) should be checking the scaffolding to make sure it is safe. If the inspector has found any damages or non-compliant areas of the scaffold, then the access ladders need to be removed and the tag updated stating the scaffold is not compliant and should not be used.

A thorough inspection of your scaffolding should also be conducted after any tweaks, fixes, or wild weather. And don’t forget to keep records of all these inspections.

If you have any questions get in touch with the team at HazardCo or have a look at our other working at heights blog here

What are Musculoskeletal Disorders?

A musculoskeletal disorder is any pain felt in the muscles, bones, ligaments, tendons, blood vessels or nerves. You can feel this pain in just one area of the body, or throughout your whole body. The pain can range from mild to severe enough to interfere with your day-to-day life.

The Data

Trades workers have had the highest number of claims by occupation. According to ACC data Ligament, tendon and muscle injuries (also known as Musculoskeletal Disorders or MSDs) made up 65% of all claims. It is the most common type of injury where someone requires more than a week off work, a whopping 1,590 injured construction worker incidents were logged with WorkSafe between Jun22 and May23.

Strains and Sprains in the Construction Industry

The residential construction industry is currently booming and subsequently the ACC claim numbers and payout costs for strains and sprains are also increasing. There are numerous factors which increase the risk of musculoskeletal injuries, these include time pressure, ageing workforces and unsafe lifting techniques.

We need to change the mindsets of workers thinking that “pain and injury is unavoidable” and make our younger workforce understand the combined impacts of repeated injuries – something that more experienced builders know very well.

It is well known that there are a range of factors that contribute to MSDs. It’s not just about a single factor such as the lifting technique (although for industries such as scaffolding and roofing, lifting and handling techniques are an important factor).

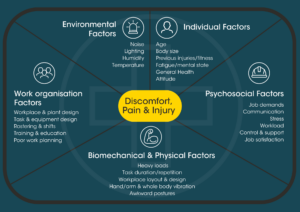

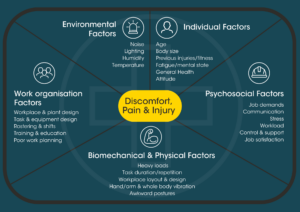

The research firmly points to five groups of factors we need to tackle when addressing MSDs in construction as shown in the diagram below these are work organisation, environmental, individual, psychological, biomechanical and physical factors:

It may not surprise you that physical factors often take most of the blame as their connection is easy to understand, measure and observe. There are also proven strategies to overcome physical factors such as machinery, equipment and task modifications.

Understanding how these factors can combine and influence each other to cause problems will be crucial. Working together and combining solutions to them in your approach is where the construction industry will get the most benefit.

The most common solutions for some of the above risk factors are:

- Micropauses and position changes

- Task rotation

- Stretch warm-up and cool down

- Cardio and strength fitness/flexibility

- Stress management

- Backcare

- Communication

- Work planning

- Early reporting

We dive deeper into what treatment might look like, prevention tips, and the unseen costs associated with MSD in the blogs below:

Musculoskeletal what treatments might look like and prevention tips

5 things you can do to tackle musculoskeletal problems MSDs in your business

Musculoskeletal the hidden costs to workers lives and businesses

If you need anymore information get in touch with the HazardCo team.

Proper management of hazardous substances on-site is important to keep everyone and our environment safe. Legally speaking, hazardous substances refer to substances which have any of the following properties:

- Explosive

- Flammable

- Able to oxidise – (create oxygen)

- Corrosive

- Toxic to humans or the environment

If you are using any hazardous substance in the workplace you need to make sure they are stored, used, transported and disposed of correctly, which will help to reduce the risk to anyone who uses or comes into contact with them.

To capture what hazardous substances you are using you must by law have a hazardous substance register along with the relevant safety data sheet (SDS).

What is a Hazardous substance register?

This is a list of all your hazardous substances (including hazardous waste) that is used, handled, or stored at any of your sites. Having a register will ensure you know the substances you have on-site, the safety measures you need to follow, and what to do in case of an emergency.

Keeping a Hazardous substance register

Keeping your register in a central location on your site means that in case of an emergency, it can be accessed quickly by anyone who needs it.

Here are some key bits of information that need to be included on your register:

- The name of the substance and, if available, its UN number

- A current safety data sheet or a condensed version of the key information from the safety data sheet

- The maximum amount that is stored at the workplace

- Where it’s located

- Specific storage requirements

- Any hazardous waste

Not only do you need the information above, but you must also make sure that the register is up to date and available on-site.

As the register represents the maximum amount of the substance held, it means it’s not going to be a daily task to keep it up-to-date. But if the maximum quantity changes, the register needs to reflect this. We recommend that you review your register each time you make a change to ensure it’s up to date and accurate.

How do I create a hazardous substance register?

Creating your hazardous substance register is made much simpler with our Hazardous Substances Register, HazardCo members can access this via the HazardCo Hub in the templates section.

Safety Data Sheet (SDS)

The purpose of a safety data sheet (SDS) is to provide key information about hazardous substances to the people who handle, use or store them or who could be exposed to them.

An SDS tells you

- The product (its name, ingredients and properties)

- Who manufactured or imported it

- How the product can affect your health

- How to use, store and transport it safely

- How to manage an emergency involving the substance

Remember it is the business owner’s responsibility to have an up to date SDS for each hazardous substance and make sure that their workers have access to it. The SDS must be less than 5 years old.

If you need a hand getting started with your hazardous substances register or would like more information, get in touch with the friendly HazardCo team today – we’re always happy to help.

When it comes to construction sites, ensuring the health & safety and wellbeing of everyone on-site is the top priority. It’s more than just wearing hard hats and high-vis vests. It involves careful planning and preparation of the specific needs, hazards and risks of each project. That’s where Site-Specific Safety Plans (SSSPs) come into play.

A SSSP is a detailed roadmap designed to ensure everyone stays safe from start to finish. It identifies the hazards, how you will minimise the risks, sets clear guidelines, and helps to create a culture of safety on-site.

Setting up health and safety with HazardCo Projects is quick and simple. All you need to do is log in to the HazardCo Hub and “create a Project”. You receive the completed SSSP straight away while the physical scan-in board will be sent out for you to display on-site.

Not only does HazardCo’s Project save you time at the start of your project, it saves time for everyone on the site. Once the project starts, everyone entering the site inducts themselves on-site using the QR code on the site scan-in board, and the QR scanner in the free HazardCo App. That’s right, everyone inducts themselves using their smartphone, no lengthy induction meetings or paperwork required, and you get a record of every completed induction too.

It’s important to get everyone on board including your subbies!

Make sure you request a Task Analysis from each of your contractors so you can include their Hazards and controls in your SSSP. This will help ensure you and others on site are well informed of all the hazards from start to end of the project.

Share the SSSP with the team. Anyone scanning into the site using your QR code and the HazardCo App will have immediate access. Every worker who sets foot on-site needs to know and understand the SSSP. This can be done during the site induction, where the workers learn about the project, potential hazards, and safety protocols, which they can do using the App. If you need more information on working with contractors you can check out this blog.

Why Go Digital?

While there’s no one-size-fits-all approach to creating a SSSP, using digital tools like HazardCo can offer great time saving and streamlining benefits. Among many other benefits of using HazardCo, using it for SSSP means that you have:

- Communication: Getting the site information to the teams on the ground

- Visibility: Anyone scanned into the site can access the SSSP.

- Reporting: You can complete site reviews, risk assessments, toolbox meetings and more for your project via the HazardCo App all from your mobile device.

- Records: Any reports logged in the App while by someone scanned into site, can be viewed and discussed at toolbox meetings. These will all be stored in the Hub and recorded against the project.

Going digital with the HazardCo App means information flows more efficiently and this allows your teams to better collaborate with one another.

So, whether you’re building a multi residential, a new build or doing a big reno, remember: safety first, always. And with a solid SSSP in place, you’re one step closer to a successful and safe construction project.

For health and safety sorted in a flash, right from the very start of your new build, look no further than HazardCo Projects. It’s the smart way to maintain a safe site and have more time to focus on the job at hand.

If you would like to discuss your upcoming project please give our team a call on 0800 555 339.

On the farm or in the factory, transport is a major part of daily life, making vehicle safety a top priority no matter what you are doing. When using vehicles you can break down transport activities into distinct areas Safe Stop, Safe Vehicle, Safe Driver, and Safe Site – so that you can better identify the hazards and take proactive steps to manage the risks.

Safe Stop

The concept of Safe Stop shows the importance of proper shutdown procedures for vehicles and machinery. The steps are straightforward but critical:

- Engage handbrake: Ensure the vehicle or machinery is securely immobilized.

- Controls in neutral: Prevent unintended movement.

- Switch off engine (or turn off power): Shut down the engine or power source.

- Remove key (or lock-off the power supply): Securely store the key or disable the power supply.

Following Safe Stop procedure is essential:

- Before leaving the driver’s seat.

- When anyone approaches the vehicle or machinery.

- Before any maintenance or adjustment tasks.

Safe Vehicle

A Safe Vehicle is one that is well-maintained and suited to the tasks. Consider the following checklist:

- Make sure vehicles are appropriate for the job and equipped with necessary safety features like mirrors for reversing and clear vision in all places.

- Conduct daily inspections, quickly report and fix any faults.

- Regularly maintain braking systems to ensure effectiveness.

Additionally:

- Install roll-over protective structures (ROPS) and seatbelts on vehicles at risk of overturning.

- Protect lift truck (forklift) and loader operators from falling objects.

- Ensure trailers have brakes matched to their loads and speeds.

Safe Driver

The Safe Driver makes sure they are competent, and fit to carry out the task:

- Confirm drivers are medically fit and properly trained.

- Prevent unauthorized individuals from operating vehicles.

- Educate drivers on safe vehicle entry and exit procedures.

Passengers should only be allowed in designated seats that do not hinder the driver’s visibility or access to controls. Mounting or dismounting moving vehicles is strictly banned for safety reasons.

Safe Site

A Safe Site is characterized by organized and secure traffic management:

- Separate vehicle and pedestrian traffic whenever possible.

- Inform visiting drivers about site-specific rules and regulations.

- Minimize the need for reversing by implementing turning circles or one-way systems.

- Maintain well-lit and properly marked traffic routes.

- Ensure silos, bulk dumps and storage areas are away from overhead power lines (OHPLs).

Additional vehicle safety tips include:

- Avoid approaching or walking near reversing vehicles.

- Use audible alarms on vehicles which activate when reversing.

- Provide separate doorways for vehicles and pedestrians in buildings.

- Wear high-visibility clothing to enhance visibility of people to the driver.

By addressing these four key areas—Safe Stop, Safe Vehicle, Safe Driver, and Safe Site—you can significantly improve transport safety.. Regular training, clear procedures, and a commitment to proactive safety measures are essential for protecting everyone involved in transport and vehicle movements.

If you need any advise get in touch or give the HazardCo team a call on 0800 555 339

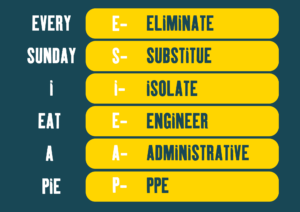

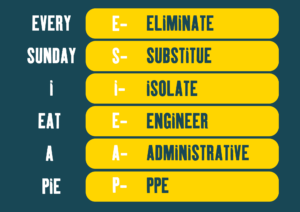

When it comes to working safely at heights, make sure you’re eating a pie every Sunday. Wait…what?

Yep, you heard that right.

Remember the phrase: Every Sunday I Eat A Pie. It’s a handy way to remember the steps for staying safe: Eliminate, Substitute, Isolate, Engineer, Administrative, and PPE. These steps help you figure out what safety measures to use when you’re working at heights.

No matter the height you are working at, you have to make sure that you are controlling the risks, it doesn’t matter if that work is 40mm from the next surface or 40m.

Just like people argue about the best flavour of pie, there are different ways to working safely at heights, choosing the best methods such as the following examples of controls will be based on your specific situation, and the work being carried out. .

Eliminate: Not everything that needs doing has to be done “up there”. What tasks can be done on the ground before you have to do it at height? Every step achieved where you don’t have a risk of dropping objects is a reduction of other things to concentrate on when at height.

Substitute: What other methods can be used to get to the workspace? Instead of a ladder could you use a scaffold? MEWPs (like scissor lifts & boom lifts) can be really handy here, not only with safe access but also with making it easier on your body to get there and work all day.

Isolate: This means to physically prevent the contact between you and the risk (falling or even dropped objects etc) this can come in the form of guardrails, scaffolding, or nets to prevent things or people from falling to lower levels.

Engineer: This is a more permanent solution, think of your handrails on staircases or cleverly built seats with high backs around the edges of a raised deck. It’s built for purpose and will continue to deliver that outcome without you having to interact with it (passive protection) this is often referred to as safety in design.

Administrative: This is simply making people aware. Think about hazard boards, signs, warnings, toolbox talks or paperwork to communicate what you will be doing, how, and who is doing it when.

PPE: This is the likes of harnesses to prevent you getting to a place you can even fall if possible, and if you do fall then to lessen the severity of the injuries you would receive from a fall if set up correctly, a hard hat to protect your head from small items falling like screws and small items etc.

Remember consistency is key

It’s important you and your team are actively involved in ensuring any work carried out at heights, is done in the safest way possible. Empower your team to speak up, highlight unsafe working situations or practices, and swiftly act to handle them.

We recommend doing a Task Analysis to put a plan in place to manage the risks involved with working at height. This will help you decide whether it’s possible to eliminate the risk of falling from height or what the most effective control/s are to minimise the risk.

So from the above, what’s your favourite flavour combinations? Which ones will satisfy your cravings to keep the team safe today?

If you’ve got a question about working at height or any other health and safety matter, the HazardCo Advisory Team is here to help. Give them a call on 0800 555 339

Looking for something in particular?

Kick off the New Year safely on site

The holidays are done and dusted, and it’s time to ease back into work. Reopening your site is just as important as shutting it down properly and the New ...

The Christmas break is nearly here. You're probably counting down the days until you can relax and spend some proper time with the family and friends.

But before you lock up for the holiday...

Good health and safety isn’t about stopping work, it’s about having simple, clear processes so everyone understands how to get the job done safely.

When you plan the work and manage the ris...

The hidden danger on-site: Silica dust

Construction sites come with plenty of obvious hazards but some of the most dangerous ones are the ones you can’t see. One of those hidden risks is res...

Slips, trips, and falls, don’t let them take you down!

Slips and trips might seem harmless, but on-site, they’re one of the biggest causes of injuries. A bit of ground clutter, a wet floor,...

Your business is only as strong as your people. When workers get injured or struggle with stress, everyone feels it through missed deadlines, extra pressure, and lost skills on-site.

The go...

Got lone workers on your team? Here’s what you need to know

If someone on your team is working by themselves without other people around and without direct supervision, they’re likely conside...

Take the Hassle Out of Toolbox Meetings

Toolbox meetings don’t need to be a paperwork mission. With the HazardCo App, you can run quick, focused chats straight from your phone – No prep, no p...

Get your team scanning in and out – it’s a no-brainer!

We get it, health and safety chats aren’t always the most exciting. But they are the most important. When everyone on-site takes part,...

Working with heavy machinery and managing traffic on-site can be risky. But with the right checks and planning, we can keep everyone safe.

Daily machinery checks

Before starting work each da...

We’re excited to announce the launch of the new HazardCo Premium plan for Agriculture, Horticulture, and Manufacturing customers. This plan is packed with extra industry-specific guided conten...

Operating Machinery

Working with heavy machinery can be dangerous. Incorrect use or untrained operators can lead to serious injuries or worse.

Training and Supervision

Machinery shou...