Managing Workplace Health and Safety (WHS) on-site is all about identifying hazards and reducing risks to keep everyone safe. The most important thing you can do is make sure that everyone on-site takes WHS seriously, from the supervisor to the apprentice.

If you don’t know where to start with H&S, check out the list of top-priority health and safety actions we’ve listed below. If you’re looking for a detailed list of all the WHS tasks you should be checking off as a home builder, download the Residential Construction Health and Safety Checklist

Key WHS construction requirements in a nutshell:

What does good health and safety look like?

- You provide a safe working environment: Your site is safe and free from hazards that could cause harm to your employees or others.

- You have WHS management system in place: A WHS management system documents how you will manage WHS risks in your workplace. The system includes processes for identifying, assessing, and controlling risks. You have a Site Specific Safety Plan (SSSP) in place for every build. The plan is customised to the unique requirements of the project.

- Your contractors are up to scratch and operate safely on site: You’ve checked contractors have good WHS practices in place and the appropriate insurance to be operating.

- You regularly communicate with workers on-site: Everyone on-site has the appropriate training, instruction and information they need to carry out their work safely. When it comes to health and safety, you can’t communicate too much!

- You collect a Safe Working Method Statement (SWMS) before High Risk Construction Work begins on-site: Importantly, the SWMS is specific to the task and the site at hand.

- You monitor health and safety performance: You regularly monitor your WHS activity and identify any areas where improvements can be made.

- All incidents are reported: Incidents and near misses on site are reported, documented and investigated. Investigating near misses and incidents will help you to understand the cause so you can put corrective actions in place to prevent similar incidents from happening again in the future. If an incident is notifiable, it is reported to the regulator.

- Nailed all these things? Download the full Health and Safety checklist

Take the hard yakka out of health and safety, with simple digital tools and expert advice when you need it. The HazardCo system will give you confidence that you’re doing all the right things on-site, in the right way. It even has a SSSP Generator so you can create a site-specific safety plan in minutes – take it for a test drive.

It’s fair to say that there will be various electrical equipment on your Construction site. To ensure your electrical equipment is safe and in good condition you should do daily inspections before use and have your equipment tested and tagged.

What is testing and tagging?

Testing and tagging is checking the safety of portable electrical appliances that get used in the workplace.

It involves two steps: Visually inspecting the appliance for any noticeable damage,

- cracked casings

- missing or damaged guards

- nicked cables; tape covering nicks or cuts

- dry and brittle insulation

- burn marks or signs of overheating

- RCDs not tripping when tested

And secondly, electrically testing it with a Portable Appliance Tester (PAT). Once tested and approved, a tag is attached with the following information:

- who tested it,

- the test date, and

- when the next test is due.

Why do you need to test and tag?

Testing and tagging helps identify any faults or damage in the equipment that could potentially cause harm to workers. Any lead or cord that is damaged or that fails testing is to be immediately taken out of use and removed offsite. If you cannot promptly remove it offsite, consider other means like attaching a durable out of service tag so as to warn workers not to use that piece of equipment.

Who can complete a test and tag?

Inspection, testing and tagging of electrical leads and cords on construction sites are required to be completed every 3 months by a competent person. A competent person is someone who has the relevant knowledge, skills and test instruments to carry out the relevant inspection and testing.

If the testing reveals any issues or something needs fixing then a registered electrical worker will be required.

What type of equipment needs to be tested and tagged?

In short, basically any electrical corded power tool or device. This includes any device or appliance that has a flexible cable, and a removable plug, and also includes both single and three-phase connections.

Keeping you and your workmates safe at work is a priority, so make sure you are aware of the businesses testing and tagging requirements on-site.

The HazardCo App site review resource has a list of electrical controls that should be in place to manage the risk of electrical hazards.

Want more information? Have a look at our other blog on RCDs and Leads – protection against electrical shock.

With every new contractor you bring on board, remember to tick these boxes to make sure they are going to hit the ground running when it comes to health and safety on-site. It’s your responsibility as the principal contractor to make sure these checks and balances are in place.

Pre-qualify the contracting company once a year

- ABN number and company details

- Insurance (work cover / income protection / public liability)

- A health and safety policy and evidence they follow good processes

There are lots of different ways you can check their health and safety processes. A policy is a good place to start, as well as examples of what they will do on-site if they have an incident and how they will record toolbox talks. You should also ask for an example SWMS for any high-risk construction work they will do.

Induction of the worker

- White card

- Trade qualifications and experience

- High Risk Work License

We recommend checking these items before they come on-site so you don’t forget. Tip: Ask for a photograph of the items for your records.

On-site induction of the worker

- Have they read and agreed to the site specific safety plan?

- Have they been made aware of any hazards on-site?

- Are they bringing any hazards on-site?

The on-site induction is your opportunity to set expectations of how you expect the contractor to participate in risk identification and management. New workers are at a greater risk of injuring themself than your existing crew so a good induction is vital in avoiding injuries and downtime.

Stay on top these checks with an automated system

Get peace of mind your contractors are good to go, with an automated system to pre-qualify your contractors, check insurance, trade qualifications and more. Because it’s automated, you won’t have to chase contractors for outstanding documents, and you’ll even get a notification if someone scans-in who hasn’t been approved.

Find out more about HazardCo’s Pre-Qualification solution here.

Even if you are self-employed you still carry the same duties under the legislation as the main contractor.

If a contractor, in turn, engages other businesses then they too must assume some of the responsibility for their work. A contractor is most likely to have the greatest influence and control of their own work activities and workers (or contractors).

There should be a way of recording your planning and the ways in which you share this information. All businesses should have access to information to keep themselves or their workers safe.

Your primary duty remains to prevent harm arising from your work. Identify risks that could arise and share information between relevant parties.

The following key steps should be followed by contractors:

Scope

- Engage with the main contractor to identify risks

- If engaging your own contractors share information relating to risks, safety plans and expectations

Prequalify

- Provide the main contractor with evidence to demonstrate your health and safety procedures eg Task Analysis, Safe Work Method Statements, Training Registers

- If engaging contractors of your own, prequalify their procedures. Make sure you are happy with how safely they will work.

- Find out more about HazardCo’s Pre-Qualification Tools here, or get in touch with the team to find out if it’s right for you.

Select

- If engaging your own contractors, select them based Select the contractors based on prequalification outcome and any other factors including availability, skills etc.

Appoint

- Complete risk assessments (e.g. Risk Assessment on the HazardCo App, Task Analysis or other risk management plans).

- Agree these with your workers and other businesses

Monitor

- Complete Risk Assessments/Site inspections/Observations at the start of the day to make the work area is safe to work in

- Hold regular toolbox meeting, so all workers are aware of safety expectations, share this with other contractors on-site where they are affected by your work

- Investigate any incidents and share the findings with the team and the main contractor

Review

- Review health and safety performance with your own workers and contractors

- If engaging contractors, review during the project and post-project review

Working along other businesses is a natural part of residential construction. Everyone on-site has a duty to open up the lines of communication and look out for each other.

When we hear the term “red flags”, we often think of warning signs when it comes to a particular situation. In the way of a construction site, this could be anything from a messy site, to using out of date H&S paperwork.

Some red flags are more visible or obvious than others, however it’s important to eliminate red flags on your site as they can cause injuries and other issues for you and your crew.

🚩 No site security fencing around perimeter

Why is this a red flag?

Not having a fence around the property perimeter could invite unauthorised entry. If your site isn’t secure, members of the public or children can enter the site, which could lead to injuries, property damage or stolen items.

How can you remove this red flag from your site?

Easy, ensure your site has adequate fencing set-up around the perimeter to prevent unauthorised entry. Take into consideration the height and ensure it’s not only high enough, but also check that the gap at the bottom isn’t too big where people including children could squeeze through underneath.

🚩 Messy site

Why is this a red flag?

A messy site can lead to all sorts of problems. Waste and other objects left lying around can create obstacles for you and your crew. These in turn could cause slip and trip injuries, something we want to avoid!

How can you remove this red flag from your site?

Make sure your team is regularly cleaning up after themselves. Waste materials like cardboard, general rubbish and other lighter material to be placed/stored in such a way to eliminate tripping hazards and prevent them from flying off site especially during strong winds. Having a skip or bins available will make this task easier for everyone to get done.

🚩 No site signage displayed at the front of the site showing the Principal Contractors details

Why is this a red flag?

The site sign provides all of the important details including an after hours contact number. If something happens on site and the principal contractor needs to be contacted, it needs to be easy to find.

How can you remove this red flag from your site?

Display a Principal Contractor sign in a visible location which includes the following information:

- Principal Contractor name

- Principal Contractor number

- Emergency contact details (e.g. site supervisor)

- Project site office (if there is one)

🚩 High risk work being performed on site without adequate controls

Why is this a red flag?

If there is no process for identifying the hazards, assessing the risks and what controls are required for a task, it could pose a significant risk to workers onsite.

How can you remove this red flag from your site?

SWMS are required for all high risk construction work. Ensure SWMS are accessible to the workers performing the task.

It’s important that SWMS are regularly reviewed. If the SWMS is not being followed due to a variation of work or conditions have changed, then work must stop until the SWMS is reviewed and updated.

🚩 Incidents, near misses, injuries and illnesses are not being reported or notified to the right people

Why is this a red flag?

There’s a few reasons why. When people are unaware of incidents or near misses occurring on site, it could lead to the same incident occurring repeatedly. The other issue is that some incidents legally need to be notified to WorkSafe/SafeWork. A fine can be given if this does not occur.

Reporting injuries is also important when it comes to making sure the worker receives appropriate treatment, (e.g. medical treatment) and other support, (e.g. return to work).

How can you remove this red flag from your site?

When incidents, near misses, injuries and illnesses occur on-site it’s important they are reported and investigated. By recording an incident via the HazardCo App, it automatically populates an incident register on your Hub so that all the incidents are recorded in one central location.

Investigations are important as they look at why the incident occurred and what controls can be implemented to prevent them from occurring again.

🚩 Out of date paperwork

Why is this a red flag?

H&S paperwork needs to be kept up to date to help keep your workers safe. If yours is out of date, it could contribute to an incident on-site.

Additionally, lack of H&S documentation (e.g. SWMS) could mean you’re not complying with Legislation so you could be liable for certain prosecutions and/or fines.

How can you remove this red flag from your site?

If you’re old school and don’t mind filling out H&S paperwork by hand, make sure you are using something that is current e.g. SWMS is specific for the high risk task.

If you’re like us and love using a digital system, use the HazardCo App to get your H&S done quickly and simply. All of our features including the SWMS and site review are regularly reviewed and kept up to date including when legislation changes.

If any of these red flags have made you stop and think, we’ve created a list so you can check off everything you need to do as a builder or trade on site.

Click here to download the Builder checklist. If you’re a trade, email our team at info@hazardco.com and we’ll send you the Trade checklist.

Why are concrete/cement/plaster products in the eye such an emergency?

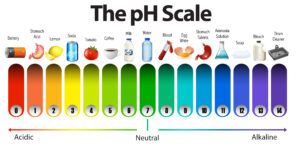

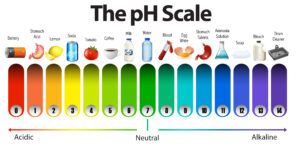

Most cement, lime, mortar, concrete, and plaster products are hazardous substances that contain strong alkalis.

As seen in the image above, alkalis are on the opposite end of the PH scale from acids, however, can be equally as dangerous, being extremely destructive to your eyes. The way you handle the first seconds, minutes, and hours after you get the dry powder or wet mix in your eyes, will determine the outcome.

Alkalis may start their damaging work in your eye without much pain or symptoms, but over time the damage gets worse. So beware, follow the first aid steps below even if you don’t feel pain.

Don’t become one of the statistics: in 2019 – 2020 there were 197 injury claims resulting from chemical or other substances to the eye.

What is the First Aid treatment if I get concrete/cement products in my eye?

Every second counts! Run to the closest tap, eye wash station or water bottle and start flushing your eye. You are aiming to dilute the alkali to lessen the damage.

Wash your face and hands, you don’t want to get more cement product in your eyes. Flush your eye with a steady stream of running water. Let it pour into your eye while lifting both eyelids to rinse out all the cement granules underneath. Do not reuse the water and do not let contaminated water run into the unaffected eye.

- Do not rub your eye.

- Remove contact lenses as soon as possible.

- Continue flushing while you or someone else calls 000, or the Poisons Information Centre on 131 126 for instructions. Have your concrete/cement/plaster Safety Data Sheet handy, as the medical services will base their instructions on the product information in the SDS (for instance, the higher the pH of the product, the longer you need to flush the eye).

- You must see a doctor urgently when an alkali has entered your eye. Continue flushing the eye en route to the medical centre. The doctor will continue flushing your eye until its pH is back to normal. Take the SDS along with you.

What will happen if I do not flush my eye, or stop too early?

If you do not flush your eye, or stop before you are told to do so, you may suffer from permanent eye damage, dry eyes, vision loss and more.

How can I protect my eyes?

- Training: everyone on-site should know about the risk, prevention, and First Aid treatment of cement/concrete/plaster products in the eye.

- Do not touch your eyes when working with chemicals

- Wear strong gloves whilst handling material. Remove gloves and wash hands prior to eating

- Nitrile or chemical-resistant gloves are best

- Wear sealed safety goggles to protect against dry cement/concrete/plaster dust, for instance when mixing, and when the risk of wet splashing is high.

- Wear safety glasses when the risk of wet splashing is low.

- Have an eye rinse station at hand and know the location of the nearest tap.

You can create a Hazardous Substances Register using the template available in your HazardCo hub. You can attach the SDS’s to the register and share it with your team.

If you have an incident where someone gets cement/concrete in their eye, remember to report this as an incident in the HazardCo App. This will automatically be added to your incident register in the HazardCo Hub, and the Advisory team will be in touch with you to discuss next steps if it is deemed to be notifiable.

For questions or support, contact the friendly advisory team at HazardCo on 1800 954 702 or info@hazardco.com.

Timber frame standing and truss erection can be back-breaking work! It is often high risk work with some serious potential injuries. We recommend these three steps are completed prior to every install. Ensure that everyone understands the process and their role, from when frames and trusses arrive on-site all the way through to standing.

Here are 3 recommendations to ensure that your site is safer during the arrival and installation of frames and trusses.

1) Risk Assessment and Safe Work Method Statement

The development of Risk Assessments and SWMS are crucial to your workers to ensure their safety throughout the build. To make these processes easy, you can complete these on the HazardCo App.

Some things to think about when creating a Risk Assessment and SWMS for frame and truss delivery and erection are:

Is the work area secure?

Clients, visitors, and members of the public cannot enter the area and workers are aware that they should only enter if they are required for the tasks.

Have all site inductions been carried out and an emergency plan developed for any at height work?

Have all workers who work at height been trained to do so? Is access to height suitable and is fall protection in place?

Have all workers been provided with the correct PPE? Are all tools and equipment available and in suitable working order for the task?

The purpose of a SWMS is to go into detail for each of the tasks to be carried out. Thinking about the hazards at each step and how they can be appropriately controlled.

You should think about:

- The delivery of frames and trusses

- Frame standing

- Truss setting

Prior to work starting, workers should be involved in developing a SWMS. Consulting workers is important so they understand the detail of the SWMS and what they are required to do to implement and maintain risk controls. Sharing information and using the knowledge and experience of workers will help make sure the work is performed safely and in line with the SWMS.

On paper, this sounds like a lot of work – but it is made simple by using the HazardCo App, and using SWMS templates that you can save as templates and amend again and again. You’re not having to start from the beginning for tasks that you complete regularly. Do remember to check over your templates before approving them as different sites can present different hazards that you don’t want to miss, (overhead power lines as an example).

2) Working safely at height

When working at height, either on a second story or setting trusses you need to ensure that your workers are safe, not just from falling, but from tools, equipment, or materials falling too.

Scaffolding

Once the lower level frames have been stood/braced appropriately, safe working platforms should be installed such as scaffolding. Scaffolding over 4m must be erected by a licensed scaffolder and all scaffolding should be checked by a competent person regularly.

Edge protection

If the potential of a fall cannot be eliminated when working on a roof, some form of edge protection should be used to isolate workers from a fall. This includes working on single-story buildings and structures. Using the existing scaffolding as edge protection is often the simplest solution. If this is not practicable, then elevating work platforms or temporary work platforms should be used. Toe boards should be fixed to temporary edge protection as a way of containing all materials, including debris and loose tools.

3) Traffic Management Plan

Worksite traffic can be a major cause of harm on work sites. When it’s close to having your frames and trusses delivered to site and you’re considering dates with the delivery company, it is essential to communicate the traffic management plan with them. This provides the company and drivers involved with a clear picture of how the site has been structured and can assist the delivery company in selecting the correct sized vehicle for the delivery, taking into account the site size and structure.

Ensuring that you implement the above can prevent many injuries on site, as well as regular toolboxes, making plans for ‘what if’ situations (rescue plans) and discussing these with your workers to keep them alert so they’ll know what to do if an incident occurs on-site.

For some useful information on the safe installation of roof trusses and framing please view these resources:

WorkSafe Victoria: Safe erection of roof trusses

WorkSafe Victoria: Preparing to erect timber wall frames

SafeWork Australia Managing the risks of falls in housing construction

Construction work involves many businesses and undertakings involved in the same task or activity (for example suppliers, contractors, and building owners). This means there may be multiple businesses that owe a duty to workers and other persons.

There may be multiple people or businesses that are responsible for the duty of care to workers and others on-site. Therefore, more than one person can have the same duty. When it comes to sharing duties, all parties have responsibility. In these situations, all parties need to consult, coordinate and cooperate so they can all meet their shared responsibilities.

Some examples of duties you are likely to share include*:

- Managing risk

Identifying hazards, assessing, and controlling the risks. If the risk cannot be eliminated, minimise it. Regularly review your controls to ensure they are effective

- Worker consultation, engagement, participation, and representation

Ensure that workers are consulted. This involves sharing information, giving workers a reasonable opportunity to express views, and taking those views into account before making decisions on health and safety matters. Consultation may also occur through the builder talking to subcontractors and asking them to share information with the subcontractors’ workers and pass any feedback back to the builder.

- Information, Training, and Instruction

Ensure that workers receive relevant information, training, and instruction to protect every individual from risks to their health and safety arising from construction work carried out.

- Notification

If a notifiable event occurs, you must notify the Regulator as soon as you become aware of the event.

- First aid

Ensure that your workers have access to first aid equipment and trained first aiders. If you share a workplace with other businesses, you can coordinate sharing first-aid resources with them.

- Emergency plans

You have a duty to prepare, maintain and implement an emergency plan at your work. Consult, cooperate and coordinate with other businesses that you share overlapping duties with to coordinate emergency procedures.

What are some ways you can ensure that people are not harmed, and that you are complying with your legal obligations?

- Set clear health and safety expectations and incorporate these into your agreements with contractors

- Ensure contractors have appropriate health and safety procedures in place

- Prepare a Site Specific Safety Plan (SSSP) for the job and share it with all workers and contractors. A SSSP, also known as a WHS Management Plan or Health and Safety Coordination Plan, may be required by your relevant state/territory (based on a contract value or in the case of WA, the number of persons likely to be on-site)

- Establish health and safety reporting requirements with your contractors. A great tool for this is to use the HazardCo App to complete SWMS, Risk Assessments, site reviews, Incident Reports, and more.

- Ensure site inductions take place. Communicate site rules and procedures to everyone who accesses the site.

- Get workers to sign in and out of the site. This can be done via the HazardCo App by scanning the QR code located on your Hazard Board.

- Set up clear requirements for information sharing for the duration of the project

- Ensure that there is effective communication between all parties (e.g. Toolbox Meetings through the HazardCo App)

- Monitor your workers and/or contractors you engage

* This is not a full list of duties, it is important to make yourself familiar with health and safety duties for your relevant state/territory or talk to our Advisory team if you have any questions.

You might have heard some rumblings that Western Australia is introducing new Work Health and Safety (WHS) laws. Work started on modernising the WHS laws way back in 2017, and after a heap of industry consultation, the new rules will be in place from 31st March 2022.

It’s a bit to get your head around, so we’ve summarised the main things you need to know as a residential builder in WA.

What is happening?

The new laws are largely based on the national model used in other states and territories, so companies will now have similar obligations and requirements across Australia (except Victoria who like to be a bit different and do their own thing).

The WHS Act is supported by three sets of industry specific regulations to suit WA’s unique conditions. One is the “Work Health and Safety Regulations (General)” which applies to all workplaces including the residential building industry. The other two are for Mining and Petroleum industries so we won’t focus on them.

Why the change?

The new WHS laws are intended to improve the protection of workers by factoring in modern employment agreements, higher penalties for companies and individuals, and introducing the term ‘person conducting a business or undertaking’ (PCBU).

Did WA adopt all the clauses from the national model WHS laws?

Some sections of the WHS laws were tailored for WA following extensive consultation. The term ‘Not used’ has replaced any clauses that don’t apply in WA.

Will there be a transition period for businesses to adopt the new laws?

Transitional arrangements will be put into place where duties are new or are substantially changed from existing requirements.

Keep in mind, the systems for identifying, assessing and controlling known hazards should already be in place, as both the WHS legislation and the previous occupational safety and health legislation already focused on the elimination or minimisation of risks.

What are some of the key changes to what is currently in place?

Based on extensive consultation and recommendations, key changes by the government include:

- Terms and definitions including the new term PCBU

- Industrial manslaughter and increase in penalties

- Prohibition on insurance for monetary penalties;

- Union right of entry was retained in the Industrial Relations Act 1979 and not included in the WHS Act; and

- A specific duty is included for providers of work health and safety services to ensure those services do not pose a risk to persons at the workplace.

What the heck is a PCBU?

PCBU is a new term and stands for Person Conducting a Business or Undertaking. This term is used throughout WHS legislation to describe all forms of modern working arrangements. As well as an employer, a PCBU can be a:

- A builder (including principal contractors and sub-contractors)

- Corporation

- Association

- Partnership

- Sole trader

PCBUs have a duty to ensure the health and safety of their workers and others like visitors and volunteers.

PCBUs have the equal duty of care to a worker, even if there are multiple PCBUs involved. For example, if you employ a contractor who brings in a labour hire worker, you, the contractor and the labour hire company all share the same duty of care to that labour hire worker. So if an incident occurs, you can all be prosecuted under the WA WHS Act.

What is Management of Control?

Management of control (MoC) is when the PCBU has MoC of the workplace, where they are required to ensure that the means of entering and exiting the workplace and anything arising from the workplace are without risks to the health and safety of any person.

Who is the Principal Contractor (PC) on a construction site?

A PCBU that commissions a construction project is the Principal Contractor for the project. That person can engage another PCBU as the Principal Contractor and authorise them to have MoC of the workplace.

A construction project can only have one Principal Contractor at any specific time.

Find out more about how how you can work with other PCBUs as the principal contractor

What are the changes to Industrial Manslaughter?

The new offense of industrial manslaughter provides substantial penalties for PCBUs where a failure to comply with a WHS duty causes the death of an individual, in circumstances where the PCBU knew the conduct could cause death or serious harm.

The criteria for convicting someone for industrial manslaughter under the WHS Act is the same as convicting someone under the current WA gross negligence law. But the WHS Act states that prosecutors no longer have to convict the company to be able to convict individual company officers.

The WHS Act includes a penalty provision for industrial manslaughter. The maximum penalty for an individual for industrial manslaughter is $5 million and up to 20 years in prison, but penalties vary based on many factors.

What are the changes to Insurance?

If you’re prosecuted under the current OHS Act, your insurance can pay for your legal fees and your penalties.

Once the WHS Laws comes into effect, your insurance can still pay for your legal fees, but when it comes to paying the penalty, company officers and PCBUs cannot take out insurance to cover fines for breaches.

What does this mean for me?

Both the old laws and the new laws require you to have systems in place to identify, assess and control hazards.

These new laws are a good prompt to take stock of your current health and safety practices and make sure you’re protecting both your crew on site as well as your business. Here is the WHS laws checklist with advice on the key things you should be ticking off when it comes to your project site.

If you’re not yet a HazardCo member, sign up for a free trial today. We can help you get your health and safety sorted – making it simple and easy to manage but without cutting corners.

We’re here to support you, so don’t hesitate to get in touch for a chat if you have any questions or concerns. Give us a call on 1800 954 702 or email info@hazardco.com.

More information

Using machinery and equipment for work on-site puts workers in close contact with powerful and fast moving tools. This makes getting the job done easier and more efficient but it does also present some risks to workers health and safety. If a worker comes into contact with machinery or equipment in an unsafe way, it can cause significant harm or injury. It is common practice to use guarding on machinery and equipment to create a barrier between the workers and the moving parts that can cause harm or injury.

Common risks and Hazards

Machinery and equipment guarding is designed to eliminate or minimise the risk of workers being harmed while completing their work. It is important to assess the hazards and risks involved with all the machinery and equipment used in the workplace. If machinery and equipment is not guarded properly, workers can sustain significant injuries due to coming in contact with moving parts.

Some common injuries are:

- Cuts

- Burns

- Electric Shocks

- Degloving

- Amputations

Because there is potential for serious harm when using machinery and equipment, it is necessary to plan a safe approach when conducting a job. This will help identify the hazards of working with machinery and equipment.

The hazard management process includes:

- Identifying hazards

- Assessing the hazard – decide if the identified hazards are significant

- Assessing the risk – decide how likely and seriously a worker could be harmed

- Controlling the hazard – either by eliminating, isolating or minimising the hazard

- Regularly reviewing and monitoring the hazards and risks.

- Create safe working methods like Standard Operating Procedures (SOP)

Choosing the right guarding

There are many different types of guards that can be used to protect workers from being harmed when using machinery and equipment. Here are some common types of guarding and examples of when they are used:

- Fixed – Screwed or fixed in place guarding to protect users from hazards. – E.g. grinders

- Self closing – the cutting edge only opens to the extent necessary to cut the workpiece E.g. drop saw

- Adjustable – Safety guarding that is movable. The guard is in place to protect the user but moves to allow the function of the tool. E.g. drop saws and skill saws

When choosing a guard, It is important to make sure the guard can actually prevent an operator from reaching into the dangerous parts of machinery and equipment. To make sure the operators are protected from the dangerous parts, the safest guarding must take into account an operator’s ability to reach into or come in contact with moving parts.

There are many different types of guards to choose from. It is important to choose guards that eliminate the potential for harm. If this is not possible, then guards should be chosen that isolate or minimise the risk to workers. It is very important that guarding is not removed or tampered with as this will increase the risk of harm to workers.

Control hierarchy

- Elimination involves removing the risk to health and safety from the work site. It is the most effective risk control and should always be prioritised.

- Minimisation is used when a risk cannot be eliminated. This is done using: substitution, isolation, engineering, administration and PPE.

Training/ Competency

Workers should be trained to competently complete the work they are required to do. Workers should be trained and educated on the purpose and function of the different types of guarding in the workplace. Make sure that workers have the appropriate training, supervision, and qualification (if required) to safely use the necessary machinery and equipment. Keep an up-to-date register of what machinery and equipment workers are trained on and competent in using.

If you have any questions about guarding machinery and equipment, give HazardCo a call on 1800 954 702.

Looking for something in particular?

Take the Hassle Out of Toolbox Meetings.

Toolbox meetings don’t need to be a paperwork mission. With the HazardCo App, you can run quick, focused chats straight from your phone. No prep, no p...

The holiday season is over and now it’s time to get back into the swing of things. Coming back to work and reopening your site is just as important as shutting it down. The New Year is the per...

When you have an incident on-site, whether it’s a near miss, an injury, or a work-related illness, it’s important to document an incident report.

Incident reports don’t need to be time-cons...

Electricity is essential on construction sites, but if the risks are not managed properly, it can pose serious dangers to people and property. Proper controls must be in place wherever electri...

Health and safety is a core part of any business but incidents and injuries on the job can still happen. According to SafeWork Australia, in the construction industry alone there were 15,877 s...

In light of the recent changes to Australia’s industrial manslaughter laws, we sat down with Glenn, one of our HazardCo Health and Safety (H&S) experts to break down what these laws mean f...

You’re probably across the recent engineered stone ban, but did you know SafeWork Australia has just come out with new rules to further protect workers from crystalline silica found in other b...

HazardCo understands that on-site first aid is about more than just sending someone on a course every few years. As an employer or principal contractor on-site, you have a legal and moral obli...

Did you know that if you’re carrying out renovation work the same risks apply as a new build? Whether you’re carrying out extensions, renovating, flood remedial work, large landscaping jobs or...

Maintaining clean amenities is just as important as keeping your site nice and tidy. Employers have a duty to provide adequate workplace amenities/facilities, including toilets, that are in go...

The reality is unsafe work at heights can have devastating consequences. Falls from heights are one of the leading causes of fatalities and injuries in the construction industry within Austral...

For building companies, scalability isn't just a buzzword – it's a necessity. Paul Dugdale of ARCA and Dale Spencer of Southern Ocean Building and Consulting (SOBAC), are shedding light on the...