The reality is unsafe work at heights can have devastating consequences. Falls from heights are one of the leading causes of fatalities and injuries in the construction industry within Australia. Preventing falls should be actively managed so that people working at heights are kept safe.

Identifying a task that could lead to a fall is the first step to keeping people safe. Before commencing, put in place the highest level of protection possible to prevent falls.

Consider how long the job will take: The duration of the job will impact how you select the level of protection. If the job is ongoing, the structures chosen need to remain stable throughout the job. You may need to reassess things like ladders and scaffolds throughout the job.

The hierarchy of controls outlines the various controls in order from the highest level of protection to the lowest level of protection. Select the safest, most appropriate control measure from the below hierarchy to prevent injuries or fatalities from falls from heights on your site.

Work on the ground or solid construction

If you can avoid working at height it should be your first option and is always the safest option. Some examples of eliminating the fall risk include using long-handled tools, relocating the task to the ground, and using extension poles for tools.

Use fall-prevention measures

If working from a height is necessary, you need to manage the risk of a fall. Fall prevention measures could be something like an elevated work platform, scaffolding, or guard railing.

Use a work positioning system

Check if a work positioning system like a travel restraint system can be used. A travel restraint system enables a person to work in a way that prevents the person from falling e.g. fixed-length lanyards and static line systems

Use a fall arrest system

Check if a fall arrest system like an industrial safety net, a catch platform or safety harness can be used. This system doesn’t prevent the fall but arrests the fall so you don’t come into contact with the ground e.g. shock absorber on lanyard or anchor point.

Ladder use

It may be appropriate to use a ladder. Ladders do not provide fall protection and as such should only be looked at as a last option when selecting the level of protection. Ladders should only be used for short duration works such as changing a light bulb or paint touch-ups.

Below is a great image from WorkSafe Victoria which has summarised the hierarchy of control measures for the prevention of falls. Click on the image below to view

Important: Where high-risk construction work includes a risk of a person falling more than 2 metres (3 metres in South Australia), a safe work method statement (SWMS) must be developed prior to work commencing.

Seek professional assistance

Working at height can often be high risk and there are experts who make it their job to complete this work safely. It is often safer and more cost-effective to use height specialists even for shorter jobs.

Make sure everyone knows what to do

Give your workers all the info they need to stay safe.. Conduct toolbox talks and remind them the importance of procedures and completing a SWMS (when required). Encourage them to watch out for each other and speak up if something doesn’t seem right.

Consistency is key

It’s important you and your team are actively involved in ensuring any heights related work is carried out in the safest way possible.

Resources

There are various WorkSafe / SafeWork websites, resources, and support tools on managing the risk of falls. Some examples include:

If you’ve got a question about working at height or any other health and safety matter, the HazardCo Advisory Team is here to help. Give them a call on 1800 954 702.

For building companies, scalability isn’t just a buzzword – it’s a necessity. Paul Dugdale of ARCA and Dale Spencer of Southern Ocean Building and Consulting (SOBAC), are shedding light on the importance of systems and technology when it comes to running an efficient, successful building company. Let’s dig into some key lessons from these experts.

Getting the right people on board and equipping them with the right tools and systems is the first step in scaling your business. To do this, identify bottlenecks in your existing processes and work out how to relieve these through either automation, delegation, or elimination. Being proactive and identifying what the critical points are in your business and making sure these run smoothly is a great way to make your business more efficient.

Knowing exactly where you are and if you are on track (or not) with your budgets is key to making sure your business succeeds. Being able to forecast to identify any problems, allows you to make changes to manage these. The best way to do this is to use integrated software that gives you oversight across your business and can also make financial forecasting more efficient which saves you time and frees you up to work on other parts of your business.

At the heart of scalability lies the ability to use software and systems to improve efficiency. The key is to use simple systems that offer both high-level overviews and can also easily drill down into the details, empowering the right people to make informed decisions quickly and easily.

Running a business is hard! And even our experts admit that there’s always something that pops up to keep you on your toes. Having the confidence to know that whatever tomorrow brings because you have created strong and resilient systems in your business you will be able to deal with those problems, gain knowledge from them and create a strategy to fix them, will mean that you will continue to build a successful business.

Watch the full video to discover the systems and integrations that Paul and Dale have used to successfully scale and take their business to the next level.

Running a safe site isn’t just about wearing hard hats and harnesses; it’s about effective communication and staying aware of what’s going on on-site. One of the most powerful tools is the humble toolbox meeting. These gatherings are the backbone of ensuring everyone on site is up to speed with hazards and safe working practices.

Download the Simple Guide to toolbox meetings to get tonnes of ideas for toolbox meeting topics.

Toolbox meetings are a forum to highlight safety expectations and encourage participation from everyone on site. They don’t need to be lengthy; a quick stand-up meeting will do – maybe even with a side of chocky biscuits to sweeten the deal! We recommend holding these meetings weekly, or at least twice a month, to keep safety at the front of everyone’s minds.

Some building companies take it a step further by incorporating toolbox meetings into their daily routine. Starting each day with a brief safety discussion helps to make safety a daily habit, rather than an afterthought.

The success of a toolbox meeting hinges on a few key factors:

Here are some prompts to kickstart discussions in your toolbox meetings:

Toolbox meetings help with communication, collaboration, and continual improvement. Remember, safety is a team effort, and toolbox meetings are where that effort begins.

The HazardCo App includes all the on-site safety reports you need, such as a handy tool to record toolbox meetings.

We all know subcontractors need to complete their SWMS before starting any high-risk construction work but did you know that as the principal contractor, you also need to ensure that a SWMS has been prepared before their work starts?

With HazardCo, it’s easy to stay on top of health and safety activity from your subbies.

Project Plus unlocks the HazardCo app for all of your subbies and it automatically shares the required reports with you, taking the hard yakka out of health & safety for everyone.

With HazardCo, your subbies can easily complete and share their SWMS and other on-site health and safety activity with you. The SWMS form guides your subbies through a step by step creation process. It gives you both confidence that potential hazards have been thought through and controls put in place to avoid harm.

With every report digitally stored on the Hub, you don’t need to chase paperwork or file it away… all your site’s health and safety documents are kept in the one place, which you can access from anywhere, at any time.

When all of your subbies are using HazardCo your on-site management becomes easier, you’re not bogged down with paperwork and all SWMS are in the same format making it faster to review than having to wrap your head around different templates.

SWMS are an essential part of managing health and safety on your site. HazardCo’s clever app makes it even easier for your subbies to create their SWMS and share it with you quickly – keeping your site safe and saving you time every day.

For help getting your subbies signed up, call the HazardCo team today on 1800 954 702.

It’s never good to find out the hard way that there’s a gas, power, water or communications line buried right where you need to put something on your site. When planning for excavation works, it is important to implement safe excavation practices to minimise the risk of injury and hitting critical services.

Digging blind can result in construction delays, increased costs and serious incidents.

Excavation work is referred to as any work involving the removal of soil or rock from a site to form an open face, hole or cavity, using tools, machinery or explosives. This includes open excavations, potholing, pit excavations, trenches, retaining walls and shafts and tunnels.

Employers have a legal duty of care to take reasonable actions to protect both the people and the services which may be affected by their work. Getting and using the appropriate information on the services is an important part of ensuring safe excavation on your site. There is a large range of options this can cover, so we will cover the basics in this article. If you have more complex excavations and want advice then get in contact with us.

Remember any ground disturbance regardless of depth can damage infrastructure networks like gas, water, electricity so you need to get the right information to keep you & the underground services safe.

First, you need to get information on what the assets in the area may be. You can get this information from Before You Dig Australia. This online system is the easiest way to request known plans from the asset owners. It is important to know that not all Asset Owners are members of Before You Dig Australia, so it cannot show you everything that is in the area of your excavation. You may need to contact any other asset owners directly to get hold of plans, drawings and information regarding their assets known positions prior to starting your work.

Wait to receive all information on the assets before commencing work, and only refer to plans that are current.

Once you have information on the assets, make sure the plans are with the workers on-site and that they have appropriate health and safety information and instruction. This information must also be made available to the principal contractor and other subcontractors, and be easily available for inspection for the duration of the work. If you have a notifiable incident the information must be kept for at least 2 years. You should also isolate work around the underground assets from the public.

Pay attention to the clues around your site such as marker posts, inspection points and metres. Never assume pipes and cables run underground in a straight line or are at their correctly specified depth, and always assume all lines are live, even if they look as though they are abandoned or decommissioned.

Remember all digging activities can damage underground infrastructure. You should conduct a risk assessment for the task so that you can identify the hazards to focus on, and put in place suitable controls. Workers involved in the excavation need to be trained and competent to do their part of the work e.g the Excavator operator is appropriately licensed.

To minimise the risk of damage and potential loss of life, it’s best practice to follow the 5 P’s for safe excavation:

Plan – Plan ahead by lodging your Before You Dig Australia enquiry at least two business days before your project begins, and make sure you have the correct information required to not just carry out the work but how to respond to any possible emergencies.

Prepare – Prepare by reviewing all available plans from the asset owners and ensure you conduct a visual inspection of the site for any items such as put lids, marker posts, external vents and any other visual clue for service location prior to commencing works. If you need further verification you could have Ground Penetrating Radar (GPR) carried out to show exactly where buried things are.

Pothole – To confirm the exact location of the underground infrastructure(s), pothole if permitted using the asset owner’s stated method as specified on the asset owner’s plan and information pack. Work slowly on this as you’re actually trying to “hit” it but without damaging it.

Protect – If potholing has occurred, protect the infrastructure by using various methods; such as communicating to all working on site, erecting barriers and marking the location of the exposed infrastructure.

Proceed – You should only proceed with your excavation work after you have planned, potholed (unless prohibited) and have your necessary protective measures in place.

Remember to stay vigilant and watch for changes in the ground/soil as you dig.

If you’ve got a question about safe excavation or any other health and safety matter, our HazardCo Advisory Team is here to help. Give us a call on 1800 954 702.

Before You Dig Australia has resources available for your state or territory and best practice guidelines. Read our blog on Managing the health and safety risks associated with excavation work.

Get your team involved in health and safety, and watch your workplace become a safer, happier place for everyone.

Under health and safety legislation, businesses have a duty to engage with workers and enable them to participate in improving health and safety. The business must:

Remember that your subbies are also considered your workers when they are working for you.

Together with your workers, you can determine the best way to meet these requirements. What is reasonable and practicable will depend on your workers’ views and needs, the size of your business, and the nature of its risks.

Businesses must:

You will need to engage and consult with workers who are directly affected by a matter relating to health and safety. This includes when:

It’s important to have meaningful and effective health and safety talks. It’s good for people and for business. This doesn’t mean hour-long talks or lots of documentation, it’s simply about approaching H&S with the right attitude and aiming to get everyone involved.

HazardCo makes it even simpler to do this with our ‘Toolbox Meeting’ feature on our HazardCo App – handy for making sure everyone on-site is keeping on top of what’s going on.

If you need a hand getting started or would like more information, get in touch with the friendly HazardCo team today.

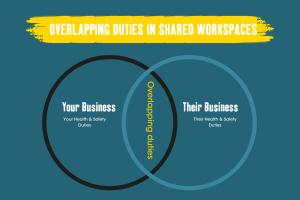

In the world of construction, it’s common for duties and health and safety responsibilities to overlap. This can be managed simply – just follow the three C’s – Consultation, Cooperation, and Coordination and you’re on your way to a safer work site!

Basically, an Employer is required to ensure the health and safety of their workers, contractors or any visitors who might be affected by work operations.

On-site this means that there can be a lot of overlapping duties, so the principal contractor is responsible for coordinating with other businesses/trades/subcontractors so they can all meet their combined responsibilities. See the image below:

When there are multiple businesses at the same site, each business must do what they can, within their control, to keep workers safe. In these situations, the most effective way to manage workplace health and safety is by working together.

By following the three C’s everyone will be aware of their overlapping duties, so roles can be clearly defined and work isn’t impacted.

Consultation between businesses can help you all reach a common understanding and establish clear roles, responsibilities, and actions in relation to work health and safety. Consultation could require discussions around:

From the consultation comes cooperation. This simply means sharing information and working together to put in place systems for managing and controlling risk agreed during the consultation process. Working together can increase the scope of the hazards recognised – ultimately making the site safer!

And last but not least – now actually making sure everything works well together. Businesses should be able to coordinate on what systems will be implemented to control risks. This isn’t about one business pushing all the duties down on another, it’s about everyone involved working together to avoid duplication, or worse, health and safety risks.

What may seem like a hassle at first, is actually a huge benefit to life on-site. Keeping people safe should always be the top priority on any construction site – and of course, Health and safety laws actually require this to be the case. Aligning yourself with other Employers on site and knowing what safety systems are in place is vital and can save lives.

If you are a principal contractor you must document the arrangements in place for consultation, cooperation, and coordination between all the different Employers at your site in your Site Specific Safety Plan (SSSP). The HazardCo system will guide you through creating a SSSP for each of your sites – Test drive the SSSP generator.

Managing your contractors and their H&S responsibilities is easy with the HazardCo system. You’ll get all the tools you need to pre-qualify contractors and check their H&S systems are up to scratch, plus everyone will be able to use the guided HazardCo app on site to create SWMS, log toolbox meetings and more. Get a 7-day HazardCo trial.

If you are a contractor and you have questions on how to best work with other businesses or the process you should follow, have a look at our Overlapping Duties: Working with other businesses blog.

Any work undertaken near live overhead electric lines carries the risk of electric shock. Touching a live overhead line with any part of the body, tools or any other equipment can cause serious injury and even fatality.

Make sure that you and your team are aware of the following steps that can be taken to manage the risk of an electric shock.

You must prepare a SWMS before work starts and make sure it includes all the potential hazards and expected controls. Collaborate with your workers in developing the SWMS, ensuring they understand how the task is to be performed.

The safest option to eliminate the risk of electric shock is to temporarily disconnect a property’s electricity supply from the electricity distribution lines so that the overhead line to the property is no longer live.

Find out who needs to know that the electricity supply will be temporarily disconnected. Such as:

Anyone who could be affected by the disconnection of the electricity supply should be told:

If work needs to take place near an overhead electric line then the worker’s body, their tools, and their equipment must be kept a safe distance away from the overhead line, or else the electrical supply must be disconnected by the approved electrical supplier. This is known as the safe approach distance, or SAD.

More information on Safe Approach Distances can be found on your state Regulator’s website or contacting the energy supplier.

Keeping you and your team safe at work is a priority, so make sure you are aware of the requirements of working near power lines. The HazardCo App Site Review resource has a list of electrical controls that should be in place to mitigate the risk of electrical hazards. If in doubt, you can give our team of Health and Safety Advisors a call on 1800 954 702.

Worksites tend to be filled with constant noise from tools and machinery.

While noise often means things are getting done, there is a downside to it. Hazardous noise can affect a worker’s physical and mental wellbeing including hearing loss, stress, and lower productivity. So to help you protect your hearing, here are a few helpful tips to keep your ears in tip-top-shape.

Understanding what makes noise on-site and how it impacts people and different areas on site is critical. Ask yourself and your workers:

Once you understand the answers to the above, you can start putting actions into place to control noise on-site.

Be sure to monitor and review the controls throughout the project, as different stages will create varying levels of noise.

The easiest way to decrease the effect of excessive noise on your site is to eliminate the source of noise completely. But, chances are this isn’t possible on a busy site.

The next best thing is to reduce noise.

A couple of easy ways to do this include:

Isolation involves creating a dedicated space for ‘noisy work’. This could be an enclosed room or area of site where all noisy work and machinery is used or placing workers in an enclosed cabin when operating mobile plant. This helps to block the path of noise and reduce the levels that reach your team.

Having a good understanding of how machinery and tools operate can help modify processes to reduce noise at the source. Engineering controls can include choosing attachments or parts that are noise reducing, or changing the way machinery and tools are used.

With noise comes vibrations. These vibrations can be just as harmful as the noise itself.

Here are a few strategies to help decrease vibrations when using machines or power tools:

It’s not possible to escape noise on-site, however we can put steps in place to help reduce the effect that noise has on us while we’re working.

We have previously shared content on what to expect when your workplace is inspected by WorkSafe/SafeWork. Now – what happens in the event that your business has received a notice from the Health & Safety Regulator?

If the Inspector identifies an issue, the Inspector will discuss with you what needs to be done to address the matter. The three types of notices that could be issued are:

We’ve put together our top recommendations on what you can do after receiving one of the above notices.

Carefully read the notice and follow all the instructions listed on the notice. This is particularly crucial if it’s a prohibition notice, as it means certain work must be stopped immediately.

Make sure the site entry report and associated notice/s are provided to the Director/ Owner of the Business. We also recommend sharing the notice with other project sites /areas of the business so that they can assess their area to see if similar issues are present or where there is room for improvement. This is a great way to improve health and safety across all areas and sites of the business and to demonstrate Health and Safety is a top priority for all.

Bring the notice to the attention of all persons whose work is affected by the notice (e.g. conduct a toolbox talk and record it in the HazardCo app). Discuss how the business will address the items and by when. We recommend you provide regular updates to the workers on this matter. If you have any Health and Safety Representative (HSRs) who represents workers whose work is affected by the notice, make sure a copy is provided to them.

Make sure a copy of the notice is put up and displayed in a prominent place at the workplace or near where the affected work is being performed (and we recommend you communicate to workers where this can be located).

Promptly discuss with relevant suitable persons who will be involved in addressing the notice (e.g. conduct a meeting with management, supervisors etc) and prepare an action plan to address all items that have been highlighted in the notice. Regularly track action items for timely closeout.

Ensure you document and record discussions, meetings, and agreed actions. Record and track health and safety actions by creating and assigning tasks on the HazardCo Hub or on the App.

Collate all the evidence that will demonstrate you have addressed all the items listed and provide it to the Inspector prior to the due date for their review.

Remember HazardCo is here to help. Give us a call on 1800 954 702 and speak to our Health and Safety Advisory team for further guidance.