Longer days and sunshine make it feel like the perfect time to crack into work. But while summer brings good vibes, it also brings its own set of risks. No matter the season, hazards don’t take a break and the hot weather can put extra pressure on your team.

So, what steps are you taking to keep everyone safe from the heat and sun exposure ?

We all know the basics: Slip, Slop, Slap, and Wrap to protect against sunburn and skin damage. But heat can be just as dangerous. Heat exhaustion, dehydration, and fatigue can creep up quickly if you’re not prepared.

Heat exhaustion happens when the body overheats from losing too much water and salt through sweat. If you don’t act fast, it can turn into heat stroke.

Heat stroke occurs when the body can no longer cool itself down, pushing body temperature to 39.4°C or higher. This is serious and needs urgent medical attention.

Heat rash and heat cramps are early warning signs, spotting them early can prevent things from getting worse.

Check out this helpful resource for symptoms and treatment options for heat-related illnesses.

And if you’ve got underlying health conditions that might be affected by extreme heat, make sure your workplace knows.

The sun is strongest between 10am and 4pm. Take regular breaks during this time, and wherever possible, schedule tasks in shaded or covered areas.

Drink plenty of water, even if you’re not feeling thirsty. Sweating means you’re losing fluids fast.

Slip on a shirt, Slop on sunscreen, Slap on a hat, and Wrap on sunglasses. Even on cloudy days, UV rays are still able to burn your skin. Here’s another great resource on protecting yourself outdoors.

Don’t push too hard. Rotate tasks and avoid heavy physical work during peak heat hours.

Just because the weather is good doesn’t mean you should work longer. Heat and fatigue affect how well you think and move and that’s when incidents happen.

Talking about heat and UV risks at your Toolbox meetings is a simple and effective way to keep your team aware of this often-overlooked hazard. And remember, you can record all your Toolbox meetings easily in the HazardCo App.

If you’ve got questions or want to chat about the risks on your site, our Advisory Team is here to help.

Give us a call on 1800 954 702

MSDs (Musculoskeletal Disorders) are the most common type of work-related injury in Australia. In fact, over half of all serious workers’ compensation claims in construction back in 2024 were linked to MSDs.

MSDs cause pain in muscles, bones, ligaments, tendons, and nerves. The pain can be mild or so severe that it impacts your day-to-day life.

Often, physical strain gets most of the attention, but the real picture is bigger. These factors work together, and understanding how they connect is key to preventing injuries.

MSDs are not “just part of the job.” With the right mindset and systems in place, we can prevent them and protect both today’s workers and the next generation.

SafeWork NSW has a free program called PErforM, designed to help businesses reduce MSDs. They run workshops both in-person and online. If you’d like to know more, get in touch with us.

Health in the construction industry is often overlooked, but it has a huge impact on workers and businesses. Physical and mental health issues are among the biggest reasons for time off work and rising workers’ compensation costs across Australia. Ignoring health risks doesn’t just harm individuals, it affects productivity, deadlines, team morale, and a company’s bottom line.

The most common health issue in construction is musculoskeletal injury (MSI), caused by body stressing. These injuries account for over half of lost-time claims in many states, and around 33% of all serious claims nationally. They often result from:

Examples of injuries include sprains, strains, bruising, and ongoing pain in the back, shoulders, neck, wrists, or knees. These can happen suddenly (like a pulled muscle) or develop slowly over time.

Construction workers are regularly exposed to hazards that may not cause immediate harm but can create long-term damage. These include, but not limited to:

Psychological risks (psychosocial hazards) can be just as dangerous. Construction workers are almost twice as likely to die by suicide compared to other employed men, and young workers in other industries. Common risks include:

To learn more, we’ve developed a great resource on How to build a mentally healthy work site which provides useful tips.

When a worker is injured or unwell, costs quickly add up. Projects face delays, skills are lost on site, replacement workers may be needed, and insurance costs rise. Poor health also affects morale, making it harder to keep skilled staff.

To keep your site healthier and safer, try:

Physical and mental health are just as important as safety when it comes to protecting workers. By planning ahead, encouraging open reporting, and supporting wellbeing, businesses can prevent injuries, reduce downtime, and build stronger, safer worksites.

If you have any further questions in regards to this topic or need more support, reach out to HazardCo and speak to one of our expert Health and Safety Advisors. You can contact us on 1800 954 702.

* Safe Work Australia reporting period of 2022 – 2023.

Maintaining clean amenities is just as important as keeping your site nice and tidy. Employers have a duty to provide adequate workplace amenities/facilities, including toilets, that are in good working order, clean, safe and accessible.

Not meeting these requirements can lead to a risk of infection, disease, psychosocial harm or infringements/enforcement from the Regulator. Regulators often actively check work sites to ensure workers have access to clean and safe amenities.

When planning amenities on your site, consult with your workers to understand what will be needed. Getting them involved will give you the opportunity to provide information, training and instruction on things like keeping the site amenities clean and reporting any problems.

More often than not portable toilets are not maintained in a safe or hygienic way. Employers must make sure that toilets are cleaned and serviced regularly, and, just like plant and other on-site equipment, safe to use and operated the way it was designed to be used.

Toilets should also:

Don’t forget, the toilet should be easy to access in all weather conditions and be placed on stable, flat ground to ensure it can operate properly.

Clean drinking water must be supplied to workers by installing site water taps as early as possible. If the mains have not been connected, provide workers with drinking water in containers, coolers or flasks.

Workers should have a clean and weatherproof area for meals and rest breaks. Using the garage or a similar sheltered area can be used and be set up as soon as possible. If they aren’t available on-site, workers should be given enough time on their breaks to access eating facilities off-site. Facilities should also include:

In the early stages of construction a worker can use their vehicle for shelter until a suitable area becomes available.

As always, if you have any questions please give our team a call on 1800 954 702 or contact us.

Updated on 26 August 2024

On 1st July 2024 an engineered stone ban will take effect in all states and territories. The ban prohibits the use, supply, manufacture, processing or installation of engineered stone benchtops, slabs or panels.

Further information is yet to come on:

Until now, the focus has been on engineered stone, however crystalline silica can be found in many other building materials. It has just been announced from 1st September 2024 changes to the crystalline silica regulations will be made to further protect workers.

This includes working out if the processing of the crystalline silica substance is high risk and putting in place additional control measures if it is. Read our summary of the Crystalline Silica rules.

A new Code of Practice will be released in all states to reflect these changes. During its development, Safe Work Australia will provide guidance to help businesses and workers understand and comply with the new regulations.

Engineered stone is an artificial product that:

If you need to repair, remove, dispose of or make any minor modifications after 1st July 2024, you will need to notify your state regulator first. Notification forms will be available from your state regulator along with any other specific information such as timeframes and re-notification requirements.

VIC – A licence is no longer needed to work with engineered stone from 1st July 2024 and no notification will be required to work with already installed stone.

NSW, SA, WA, TAS, QLD – Notification forms will be available from your state regulator before 1st July 2024 and you will need to submit the form before starting any work.

NT – Written notification will be required every 12 months. The form will be ready before 1st July 2024.

ACT – Notification is required from 1st November 2024 and you will only need to notify once.

Remember, before starting any of the work you must have control measures in place to minimise the dust and you must wear respiratory protection.

Creating a SWMS in the HazardCo App can help you with selecting the right controls for the task such as using water suppression or on-tool dust extraction, and a minimum P2 dust mask or respirator.

There are plenty of silica-free options out there to suit every budget such as timber, stainless steel, and laminate options have come a long way, such as these Contact Sheet options from Laminex.

https://www.safeworkaustralia.gov.au/esban

https://www.safeworkaustralia.gov.au/esban/faq

https://www.worksafe.vic.gov.au/frequently-asked-questions-engineered-stone-ban

Information correct as of: 24th June 2024

MSDs, also known as Musculoskeletal Disorders are one the most common types of work-related injury in Australia, with construction accounting for 14% percent of all serious workers’ compensation claims in 2021-2022.

Musculoskeletal pain refers to pain felt in the muscles, bones, ligaments, tendons, or nerves, and you can feel this pain in just one area of the body or throughout your whole body. The pain can range from mild, to severe enough to interfere with your day-to-day life.

There are numerous risk factors to address: Time pressure, ageing workforce, awkward postures for a start. We need to change mindsets that pain and injury are unavoidable and make our younger workforce understand the cumulative nature of these problems- something that most ‘broken´ builders will know very well

It is well known that there are a range of factors that contribute to MSDs. It’s not just about a single factor such as the lifting technique (although for industries such as scaffolding and roofing, lifting and handling techniques are an important factor).

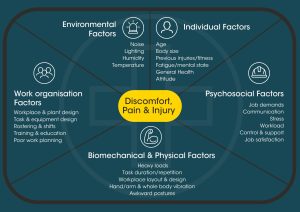

The research firmly points to five groups of factors we need to tackle when addressing MSDs in construction as shown in the diagram below these are work organisation, environmental, individual, psychological, biomechanical and physical factors:

It may not surprise you that physical factors often take most of the blame and focus as their connection is easy to understand, measure and observe. There are also proven strategies to overcome physical factors such as machinery, equipment and task modifications. Combining the other factors into your approach is where the construction industry will get the most benefit. Understanding how these factors can combine and influence each other to cause problems will be crucial.

The most common solutions to dealing with MSD are:

We dive deeper into what treatment might look like and prevention tips, and the unseen costs associated with MSD in the blogs below:

Musculoskeletal – What treatments look like and prevention tips

Musculoskeletal: The hidden costs to workers lives and businesses.

5 things you can do to tackle musculoskeletal problems (MSDs) in your business

SafeWork NSW and WorkSafe Queensland offer a simple program called PErforM, which helps workplaces effectively manage hazardous manual tasks and reduce musculoskeletal disorders. You can contact advisory@hazardco.com for further details.

It’s no secret being a tradie is a very physically and mentally demanding job, with long workdays and weeks placing the body under intense physical and mental strain.

Worker fatigue is one of the biggest hazards on-site. Fatigue can come in many different forms and be caused by a number of different factors. While fatigue may not be avoidable in today’s busy cycle, it is important we recognise the signs of fatigue and the steps we can take to reduce it.

Because at the end of the day, a tired worker is a dangerous worker.

When you are fatigued, you are less alert and aware of your environment; this can lead to an increased risk of errors, resulting in injuries or incidents on-site.

When working on-site, it is both the Employers and the Worker’s responsibility to recognise and reduce worker fatigue.

As an employer on-site you are required to provide a safe working environment, and that includes reducing fatigue. Here are a few strategies for ensuring everyone stays fresh:

Everyone is personally responsible for turning up every day in the best mental and physical conditions possible so that what you do on-site doesn’t affect the health and safety of others. Here are some tips:

Our bodies operate differently during the cooler and warmer months. During winter, fatigue levels tend to increase. With the colder temperatures, longer nights and reduced sunlight, our bodies naturally tend to shut down earlier in the day. During summer, we benefit a lot from longer days and more sunlight, however we need to consider fatigue due to hot weather and maintaining our hydration levels.

Fatigue is something that we all face in our busy work lives and it is often unavoidable.

However, it is critical we can recognise the signs of fatigue in ourselves or someone on-site and take the necessary steps to prevent fatigue-related problems from happening.

Everyone should make an effort to stay healthy… not just people working in construction. However, there is often a need for specific health checks to monitor the impacts on our health while working on construction sites.

Health monitoring is a proactive way of ensuring your team isn’t at risk in the workplace. It’s focused on the most common health risks on construction sites – hearing loss and exposure to dust (e.g. silica or asbestos dust). Health monitoring does not include general wellbeing checks or programs, since things like cholesterol checks and healthy living programs aren’t specific to construction work.

As an Employer, health monitoring is something you need to provide for any of your team who may be exposed to hazards that may cause long-term health-related issues (e.g. silicosis, asbestosis, mesothelioma, noise-induced hearing loss). It’s intended to detect the early signs of ill health or disease, helping you monitor and protect your team from exposure to construction-related health risks. You’ll need a registered medical practitioner with experience in health monitoring to perform the medical tests.

Monitoring the health of your workers is not an alternative to effective hazard control measures, rather, it helps you understand the effectiveness of the controls being used on-site. If a worker’s health is being affected by exposure to construction-related health risks it’s best to find out as early as possible and prevent any further harm to that worker or any other team members.

You have a legal responsibility to monitor workers’ health. Make sure you complete regular Site Reviews on the HazardCo App, as this will help you identify hazards and put an effective health monitoring plan in place.

Remember, like all on-site health and safety, prevention is where it’s at. To ensure you’re meeting your legal requirements when it comes to health monitoring, get on-site with the HazardCo App, and complete an Site Review today.

We don’t need to tell you that asbestos is a big deal. The dangers of the substance are common knowledge. And knowledge is power, in this case, more so than most: the power to save lives.

With this in mind, we’d like to give you some basic information on the dangers of asbestos, where it can be found and what you can do to avoid it.

There are two types of asbestos:

Inhaling asbestos fibres can cause a range of irreversible damage and diseases. Damage may occur in as little as five years or as long as 40-50 years later. Many people will not realise they have been exposed until it’s too late.

Approximately one third of all homes in Australia contain asbestos products. On 31st December 2003 asbestos was banned in Australia. Therefore any building constructed up until then has a high probability of containing asbestos. Remember, if you’re planning to renovate or partially demolish a building, have a survey done first to identify if asbestos containing material is present. If it is, contact your local Licensed asbestos removalist.

Yes – as long as strict guidelines are followed. Bagging and wrapping asbestos pieces is essential in any sort of removal – and dumping asbestos-containing materials can only be done on authorised sites. We advise you to leave this to the Licensed asbestos removalists.

Recognition means everything when it comes to asbestos. From sticking up posters on-site to equipping your team with knowledge of asbestos dangers through the HazardCo app, educating your workers could be the difference between life and death.

There are many asbestos awareness and training courses available online and face to face for further education and training.

Got Questions? Reach out to the HazardCo Health and Safety Advisory Support Team on 1800 954 702 to talk it over.

WorkSafe Vic

WorkSafe QLD

SafeWork NSW

SafeWork SA

WorkSafe TAS

WorkSafe NT

Worksafe ACT

WorkSafe WA

You may have heard about the dangers of silica dust. And that it causes a progressive, irreversible, untreatable and potentially fatal disease of the lungs called silicosis.

You may know that dry sandblasting, grinding, cutting, sanding, polishing, and drilling of silica-containing materials like concrete, rock, glass, asphalt, cement and particularly engineered stone are hazardous tasks in construction. Why? Because you create silica dust that is too small to settle. It floats around undetected in the air that is breathed in by you and those around you.

WorkSafe Victoria’s free “stonemans’ screening project” diagnosed 29% of engineered stone workers with silicosis in 2019/2020, and a similar campaign in 2021 in Queensland, Australia, diagnosed 20% of engineered stone workers with silicosis – some are young, and some are without symptoms as yet!

Tiny silica dust particles can penetrate your respirator if you aren’t careful. Make sure your respirator has been fit-tested and isn’t worn over a beard. You must also have the correct filters, as Silica dust is 100 times smaller than sand and can penetrate some filters.

Knowledge will empower you to make wise choices:

Damage to the lungs from silica dust and symptoms of disease may not appear for many years. Workers may not show any symptoms, even at the point of initial diagnosis, which is why prevention and health monitoring are critical. Often workers are diagnosed during routine health monitoring, as chest x-rays may show scar tissue formation even if you are without symptoms. Silicosis symptoms may include a dry cough, shortness of breath, fatigue, fever, chest pain and unexplained weight loss. Silicosis also increases your risk for other conditions like lung cancer, chronic bronchitis, kidney disease and some auto-immune diseases.

Tell your doctor about your current or previous exposure to silica dust. To rule out silicosis, respiratory questionnaires, lung function tests, chest X-rays and CT scans may be required.

Early detection of silicosis, before symptoms develop, can motivate you to stop further exposure, and thereby improve your health outcome.

If you were exposed to silica dust currently or in the past, even if you wore respirators and even if you have no symptoms, you need routine health monitoring. Talk to your employer. Tell your doctor about your exposure. Engineered stone workers must see specialist occupational health doctors. Early detection is most important!

Treatment is limited to relieving symptoms. For instance, oxygen therapy and bronchodilators will allow you to breathe more easily. Advanced silicosis requires lung transplants.

It is important to understand that depending on the State/Territory you are working in, there are very likely specific requirements you need to meet to ensure you are appropriately managing the risks. The state regulators have plenty of information available to learn more. We have provided a few key links below for you: