Heavy machinery and managing traffic on-site

Jun 02, 2025

Working with heavy machinery and managing traffic on-site can be risky. But with the right checks and planning, we can keep everyone safe.

Daily machinery checks

Before starting work each day, make sure your equipment is ready to go:

Visual checks (before starting the machine):

- Check fluid and oil levels; look for leaks.

- Ensure tyres are free from damage and in good condition.

- Confirm safety mechanisms are in place and working.

- Make sure warning signs are visible and readable.

- Inspect attachments, clips, and pins for damage.

- Look over hydraulics for any issues.

Stationary function test (with the machine on):

- Test the horn and reversing alarm.

- Check that lights, pedals, and controls work properly.

- Move the bucket and arms to ensure they operate smoothly.

Moving function test:

- Test the steering.

- Ensure brakes are functioning correctly.

Using your manufacturer’s checklist or the HazardCo Heavy Machinery Prestart checklist can help you cover all these points.

Managing site traffic

Keeping vehicles and people safe on-site requires a solid traffic management plan. Here’s what to consider:

- Traffic direction: Plan routes for vehicles, cyclists, and pedestrians.

- Delivery areas: Set up clear zones and schedules for loading and unloading.

- Site layout: Define speed limits, traffic flow, and place barriers or fences where needed.

- Safe practices: Establish procedures for loading, unloading, turning, and reversing.

- Site restrictions: Be aware of noise levels and traffic volume.

- Unattended sites: Plan how excavations are managed when no one is around.

- Emergency procedures: Have clear steps in place for emergencies.

Discuss this plan during site inductions so everyone knows the rules and expectations.

Know your limits: Zone of influence

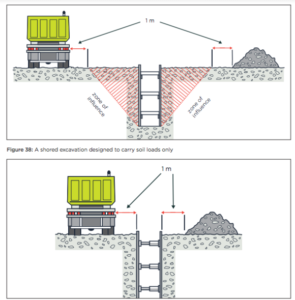

Heavy machinery can affect the stability of excavations if operated too close. Keep all heavy vehicles, materials, and spoil at least one meter outside the zone of influence unless specific designs support closer operations.

Preventing tip-overs

Uneven ground can cause machinery to tip over, leading to serious injuries. To prevent this:

- Planning: Supervisors and operators should assess the area before work begins.

- SWMS: Make sure a SWMS has been prepared.

- Risk assessment: Operators should evaluate risks before starting each job.

- Safe routes: Choose the safest paths for moving machinery.

- Digging practices: Never dig underneath an excavator.

- Distance: Work at a safe distance from excavation edges.

- Procedures: Have standard operating procedures in place.

- Design: Ensure work areas are designed to control hazards.

- Safety features: Equip cabs with roll-over and fall-over protection; operators should wear seat belts and keep doors closed.

- Exits: Ensure there are always two exits from the excavation.

If you would like more information head over to our website or to chat with one of our friendly Advisory team please give us a call on 1800 954 702.