Over the next 5 years Australia’s multi-dwelling construction industry is expected to grow due to urbanisation and strong population growth. Despite having a downturn in recent years, the number of businesses in the industry has grown 1.9% per year, reaching 27,700 in 2024.

What is Multi-Dwelling Housing?

In Australia, “multi-dwelling housing” refers to residential developments with three or more dwellings on a single lot, each with ground-level access, and excludes apartment buildings.

What’s the difference?

The key difference between single and multi-dwelling housing is the level of complexity required to manage the build and the likelihood of additional layers of responsibility e.g. directors and development owners above the principal contractor.

There are often complex stages of these builds, which are generally run by specialised subbies e.g. planning (engineers, architects, quantity surveyors), and build stages (civil works, construction management, carpentry/joiners, concreting) etc. In addition, there are often more intricate designs, additional fire safety regulation and stricter compliance standards.

Multiple dwellings also mean more trades are on-site working in close proximity to each other, and on top of that sites are located in more established areas where there is more interaction with existing residents and the general public.

Multi-dwelling Project Requirements

Because multi-dwelling housing creates more risk on-site due to the increased amount of subbies, machinery, equipment, and high-risk work taking place, It’s important that you have the right H&S tools in place for your contractors and a safe system of work e.g. Site Specific Safety Plan (SSSP) for all multi-dwelling projects.

A SSSP for a multi-dwelling build will outline how all involved parties will manage health and safety on-site. This includes details between parties on how they will manage workers, their expectations, roles, and responsibilities to ensure that all relevant site safety information is available.

Due to the potential complexity of multi-dwelling builds, we always recommend a more detailed and customised SSSP to manage risks effectively and reduce overall risk to the business and the workers.

The extra complexities that can need extra planning and control include:

Got a new multi-dwelling build kicking off?

Project Pro and the HazardCo system are suitable and capable of meeting the H&S requirements of multi-dwelling builds, so you can feel confident that HazardCo can support you as your business grows.

If you are a builder starting to diversify, now’s the right time to review your Health and Safety activity.

That’s where HazardCo comes in. If you’re building 3 or more dwellings within a fenced-off section, you will need HazardCo’s Project Pro. This is a customised project, specifically for your build that gives you everything you need for your team and all the subcontractors you will have coming onto the site.

Here are some key components of Project Pro that will help you cover all your bases.

If you have a new multi-dwelling residential project kicking off, give us a call on 1800 954 702 or email info@hazardco.com to discuss your requirements and what you need to be thinking about from a H&S perspective and the added complexities that come with it.

Good health and safety processes and systems lay the foundation for success with any project but are even more important with bigger builds and multi-dwelling residential projects.

This blog will dive into managing health and safety in complex construction projects and look at how to set up effective systems to lay a solid foundation for your next big project.

At HazardCo, we keep a close eye on industry trends to make sure our content and tools are relevant and useful. Over the last 12 months, there has been a significant increase in council consents for multi-dwelling residential projects. There are now more consents issued for multi-dwelling projects than stand-alone builds.

Multi-dwelling projects are bigger, more complex, and have more layers of shared duties, creating a need for a solid health and safety plan from the very start of the build. We also consistently see that businesses that set up good processes and systems within their business and who have a strong safety culture, do better than their competitors who don’t invest in these areas.

In talking to our customers, we’ve encountered several myths about multi-dwelling projects:

In multi-dwelling projects, shared duties are unavoidable. All businesses involved must consult, cooperate, and coordinate with each other. Good communication and sharing information is critical to managing these overlapping responsibilities and creating a safe site.

To incorporate consultation, coordination, and cooperation into your construction business, start by planning each stage of the work and think about how it affects your contractors, other businesses and the public. In this process, you need to identify the risks that need to be managed and talk to who is impacted about how to handle them. With your contractors, decide who’s best to manage each risk and make sure everyone knows their roles, responsibilities, and what’s expected of them.

Compared to standalone residential projects, multi-dwelling builds involve more contractors, equipment and activities on a smaller site, which increases risks. Key considerations include:

Contractor management and the logistics of contractors on site is a major challenge on multi-dwelling projects. Successful contractor management starts before they even enter on to a site, and involves checking contractors have the right qualifications, health and safety processes, and a good track record. Pre-planning and continuous monitoring of your contractors, when they are on site, is essential to prevent injuries and ensure smooth project execution.

If you would like to know more about contractor management, check out our Simple Guide To Contractor Management.

Key high-risk areas in multi-dwelling projects create another unique challenge for these projects and can include the following:

Businesses that have good processes and systems in place do better across the board and they are more likely to complete projects on time and on budget. This creates happy clients and a better reputation in the industry.

Successful multi-dwelling projects often include:

The shift towards multi-dwelling residential projects brings new health and safety challenges. By debunking myths, understanding shared duties, managing contractors effectively, and focusing on high-risk areas, you can make your sites safer! Remember, health and safety planning is not just a regulatory requirement but a vital part of protecting the crew on site.

If you have a new project in the pipeline, let’s work together to keep your sites safe and successful. We have specifically designed Project Pro to meet the complex needs of multi-dwelling residential builds which includes extra support from our advisory team. Get in touch today!

Adverse weather has the potential to hit hard, with strong winds, extreme temperatures, and rain. All of these factors can cause hazards for you and your workers. From trips and slips to numb fingers, heat stroke and damaged gear and equipment, varied temperatures call for specific measures to ensure that your workplace is safe.

Work doesn’t always stop when adverse weather rolls in, so it’s important to know what to do to keep your workers safe. However, if conditions become unsuitable or too dangerous, work should be paused until it is safe to continue.

Vehicle accidents don’t just happen on the roads; they can also happen within the work site. Highlight to your team that driving rules for the road also apply to your workplace, and it’s important that they take care while operating work vehicles and equipment. To make sure your vehicles and plant are safe before use, complete either a Vehicle Checklist or Pre-Start using your HazardCo App. Avoid driving if conditions are too hazardous to ensure safety.

The last thing you need is for the weather to catch you by surprise. Keep an eye on the weather forecast so your workers can prioritise the work that will be affected should the weather take a turn for the worse, and ensure they have the right gear to do the job safely.

Be vigilant when ensuring that workers are wearing proper PPE and suitable clothing when adverse weather conditions are present.

Follow these tips to optimise your crew’s safety so you can enjoy a productive season while keeping your team safe.

If you have any questions you can contact our Advisory Team on 1800 954 702.

Each year, an increasing number of builders are adopting construction software to streamline operations both on-site and in the office. Companies that have well-established systems and processes, especially digital ones, are able to build strong, resilient businesses ready for any challenge. If you’re still buried in paperwork and bogged down by time-consuming tasks, it’s time to explore the latest in construction software. Go digital and set your business up for success in 2025.

Here are some of the top tools to help you level up:

Construction management and estimating software

Buildxact is job estimating and job management software designed specifically for residential builders, renovators and trades. It’s the market-leading option for Aussie builders who want to run their construction project from takeoff to the final invoice, all-in-one place.

Buildxact continues to evolve and bring out new tools. It now integrates directly with your favourite suppliers to get the latest prices, which makes the quoting process quicker and more accurate. And a new mobile tool connects you with your on-site crew, to make sure you never miss a beat from the job site again.

Take advantage of estimating software uniquely designed for residential builders and trades.

Learn more about Buildxact.

A simple health and safety system

HazardCo is a health and safety system that makes WHS simple, giving you the confidence you’re keeping your crew and business safe while cutting the time you spend on paperwork.

HazardCo’s aim has always been to give their members the systems and advice they need to make their job safer and easier to do. Their digital tools do exactly that. It’s what you need, when you need it… all from your back pocket!

Property Information

Looking for an efficient way to search for potential sites and check feasibility? Conducting due diligence and reconnaissance from your laptop is really easy with Landchecker’s on-map functionality.

Quickly and easily searches properties to identify key insights, such as; heritage overlays, flood zones, bushfire-prone areas property boundaries, site dimensions, zoning maps, planning permit applications, topography, precinct structure plans, last sold price and more.

Access property titles and plans at competitive prices with one click purchase.

All paid plans now come with High-Resolution Aerial Imagery so you can analyse geospatial data for a “full-picture” view that reveals how potential development site locations/suburbs are

changing over time.

Client budget validator

ProCalc saves builders’ time by identifying unviable quotes before you invest time in creating them.

Backed by data from thousands of residential Australian projects, ProCalc enables builders to:

Builders use ProCalc to:

Built by Builders, for Builders, ProCalc fills the gap in qualifying which prospects can afford your services—helping you prioritise your time more effectively.

Start your free ProCalc trial today!

Experience how ProCalc can streamline your estimating process and help you close more profitable jobs.

Digital Warranty and Maintenance

Gtee offers a digital solution for managing all the warranty and maintenance information for your clients. You no longer need to collate this information, simply select the products you have used from Gtee’s product database.

It saves admin time, is cost-effective at $290 per build, and provides clients with 24/7 access to their digital accounts. It will also send automated maintenance reminders.

Gtee ensures legal compliance with warranty and maintenance requirements and allows builders to provide evidence of notifications for any warranty claims. The accounts are guaranteed to be active for at least 15 years.

Pre-accounting software

Dext provides automated accounting solutions for the construction industry, simplifying bookkeeping for more accurate, efficient and productive financial reporting and performance. Rather than expecting employees to spend hours manually entering expenses data into spreadsheets, professionals can use Dext Prepare to capture documents quickly and accurately. This not only makes records more accurate and consistent but it also frees up time for teams to focus on other valuable tasks.

This solution enables business owners to snap paper receipts and financial documents with one click using the mobile app, forwarding paperwork via email or uploading it directly into the software. Dext does the hard work of capturing, extracting and categorising the relevant data, so it’s ready to be published into their accounting software of choice. This makes it easier for builders, plumbers, electricians and any industry workers to ensure their accounts are organised, keep track of expenses, accurately quote projects and make informed decisions to boost revenue and productivity.

With Dext Prepare, construction business owners can enjoy:

Find out why businesses owners of all industries choose Dext Prepare.

Accounting software

Xero is online accounting software for your building company which makes it super easy to automate your admin. Plus, you can work from anywhere, even your ute!

When it comes to construction accounting, if you don’t do it regularly it’s easy to fall behind and things can quickly get out of control. By building accounting into your regular workflows you’re always on top of it. Xero is cloud-based and simple to use. Whether you are on-site or in the office you can access Xero on your smartphone or tablet so you’ll never get behind.

Xero connects to your bank, bookkeeper, accountant and other financial apps you might use such as Dext.

Find out more about Xero.

Thank you to everyone who entered our ‘Win a $4k Holiday’ competition during October. Keep an eye out in your inbox for our health and safety updates.

Congratulations to the winner:

Tools, vehicles, and heavy equipment all create vibrations that can affect your body. This is a normal part of any tradie’s day, whether you’re picking up power tools or jumping in the ute. It’s so common that many don’t realise the potential harm these vibrations can cause. However, it’s something you should start thinking about and being aware of.

How are workers harmed?

Vibrations are a natural part of working on any construction site but they do create a risk to you and your workers. Repeatedly using vibrating hand and power tools, or being around vibrating vehicles and machines can lead to serious and lasting harm to your blood vessels, nerves, and joints. Many of the most commonly used items give off some form of vibration. Here are the most common ways tradies are exposed to vibrations:

While these are the most common forms of exposure, the below should also be considered as they increase the risk of overexposure to vibrations:

Early warning signs

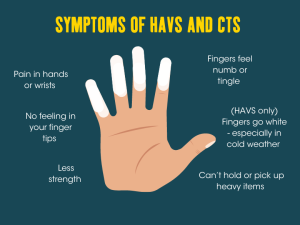

We understand that for many tradies, working with vibrations is a natural and unavoidable part of the job. With that in mind, there are a few warning signs and symptoms of overexposure to keep an eye out for:

If you are continually exposed to vibrations especially in your hands and arms you can develop hand-arm vibration syndrome (HAVS) or carpal tunnel syndrome (CTS).

What you can do to manage risk

It is up to everyone on-site to look out for each other. Consultation with your team should take place to make sure an environment can be created where excessive exposure to vibrations are eliminated or minimised.

Below are simple yet effective ways to either eliminate or minimise the effects.

Above all else, be aware that vibrations can be extremely harmful, especially when you’re exposed for lengthy periods of time.

Your best tool for minimising the effects of vibrations is to start a conversation with your boss, or your team, and put steps in place to look out for each other and your equipment.

If you have any questions please reach out the the HazardCo team

Updated on 26 August 2024

On 1st July 2024 an engineered stone ban will take effect in all states and territories. The ban prohibits the use, supply, manufacture, processing or installation of engineered stone benchtops, slabs or panels.

Further information is yet to come on:

Until now, the focus has been on engineered stone, however crystalline silica can be found in many other building materials. It has just been announced from 1st September 2024 changes to the crystalline silica regulations will be made to further protect workers.

This includes working out if the processing of the crystalline silica substance is high risk and putting in place additional control measures if it is. Read our summary of the Crystalline Silica rules.

A new Code of Practice will be released in all states to reflect these changes. During its development, Safe Work Australia will provide guidance to help businesses and workers understand and comply with the new regulations.

Engineered stone is an artificial product that:

If you need to repair, remove, dispose of or make any minor modifications after 1st July 2024, you will need to notify your state regulator first. Notification forms will be available from your state regulator along with any other specific information such as timeframes and re-notification requirements.

VIC – A licence is no longer needed to work with engineered stone from 1st July 2024 and no notification will be required to work with already installed stone.

NSW, SA, WA, TAS, QLD – Notification forms will be available from your state regulator before 1st July 2024 and you will need to submit the form before starting any work.

NT – Written notification will be required every 12 months. The form will be ready before 1st July 2024.

ACT – Notification is required from 1st November 2024 and you will only need to notify once.

Remember, before starting any of the work you must have control measures in place to minimise the dust and you must wear respiratory protection.

Creating a SWMS in the HazardCo App can help you with selecting the right controls for the task such as using water suppression or on-tool dust extraction, and a minimum P2 dust mask or respirator.

There are plenty of silica-free options out there to suit every budget such as timber, stainless steel, and laminate options have come a long way, such as these Contact Sheet options from Laminex.

https://www.safeworkaustralia.gov.au/esban

https://www.safeworkaustralia.gov.au/esban/faq

https://www.worksafe.vic.gov.au/frequently-asked-questions-engineered-stone-ban

Information correct as of: 24th June 2024

Respiratory Protective Equipment (RPE) is essential gear for protecting you from inhaling hazardous substances. In this blog, we’ll explore the important role of RPE, whether you are dealing with airborne contaminants like asbestos, fumes, dust, or working in a confined space, RPE is an essential personal protective equipment (PPE) that makes sure you can breathe safely. Join us as we deep dive into the different types of RPE, their applications, and how they can protect you from potential health risks.

Before you even get started with RPE, make sure you have other practical control measures in place first; such as local exhaust ventilation or direct dust-extracted tools with a vacuum catchment to get rid of the majority of contaminants in the air. You should also be keeping an eye on your team’s health and workplace conditions to ensure that, over time, they aren’t being made sick or getting injured by their work.

Remember, there is no such thing as a healthy dust, even if you are outside!

We’ve gone ahead and put together a quick guide of factors to consider when providing your workers with RPE.

Disposable respirators are good for short term or one-off use and when you have existing controls in place to give you extra protection. When using a disposable respirator you need to make sure a seal has been created to protect you from harmful particles such as dust, fumes and fibres.

Respirators use replaceable filters to remove contaminants to clean the air for the wearer. They come in half-face and full-face versions. The cartridge filters are specific to certain types of contaminants, ask your manufacturer exactly which cartridge you should be using for the respirator you have and the contaminants you will be facing.

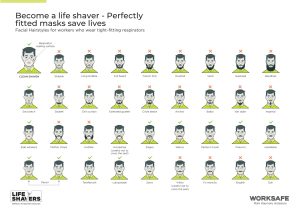

Remember if you have stubble or any facial hair you may not be getting the seal and the protection you think you are! So if you love your bread as much as your lungs read on to find out what you can do

Powered air purifying respirators (PAPRs) consist of headgear and fan assembly that take contaminated air, filters it, and then delivers the clean air to the user. These are also known as positive pressure systems. These not only keep you nice and cool, but offer the highest protection there is for people who have facial hair. Something to note with these is that the visors and headset can be impact rated if you need it, and don’t fog up because of the airflow.

Supplied air respirators provide a supply of clean air to the wearer from a source such as an air compressor or cylinder. It’s important to note that the air supply needs to be checked regularly to make sure that it is safe to use – just think about what you see coming out of your air compressor when you release the valve under the air tank! The user must also be trained in how to use the system.

It’s important for your workers to be trained in using and maintaining their RPE. They should visually check their RPE for signs of damage before each use to identify any issues, including whether it needs to be cleaned or decontaminated.

Make sure your team keep their RPE on while working in the hazardous area. Removing it for even a short period of time is a risk to their health.

Did you know that they come in different sizes? One size does not fit all!

If your workers are using RPE then make sure they are fit tested, this way you will know who needs what size, otherwise it may not work and give the protection your workers need.

The manufacturer of the RPE can tell you who can do this testing.

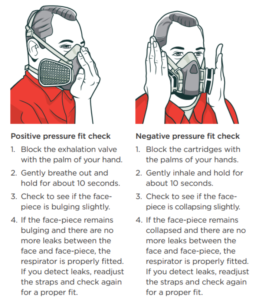

There are two checks which you need to do each time you use and RPE:

1 – check for damage visually to the sealing surfaces and straps

2 – check the valves are functioning correctly like WorkSafe images below

Image Source: Worksafe New Zealand

Keep in mind that if your worker’s safety glasses fog up while they are wearing a half-face respirator, this is a sign that there is a leak at the top of the respirator which means they are not getting full protection.

When your workers are wearing respiratory protective equipment at work, they must be clean shaven to ensure it is forming a seal and protecting them from breathing in hazardous materials. Even a small amount of stubble can prevent RPE from sealing correctly which means your workers will still be inhaling harmful materials which may cause health concerns. A clean shave goes hand in hand with the correct RPE for the job.

It’s your legal responsibility to monitor your workers’ health. Make sure that you are completing regular Site Reviews on the HazardCo App, as this will help you to identify potential hazards and put effective plans in place. Your HazardCo Advisory Team is available throughout the day to guide you through this – call 1800 954 702 to talk it over.

Image source WorkSafe

How to reduce psychosocial hazards on your work site

The workplace hazards that create risks of harm to psychological (mental) health are known as psychosocial hazards. These hazards, when excessive or prolonged, can cause serious harm. It can have a significant impact on workers, their families and business.

Construction workers are six times more likely to die from suicide than an accident at work. Every year 190 Australians working in the construction industry take their own lives; this means we lose a construction worker every second day to suicide. Young construction workers are two times more likely to take their own lives than other young workers.

Psychosocial hazards can come from:

What are some of the work related factors that affect a mentally healthy work site?

Whose responsibility is it to manage psychosocial hazards?

Workplaces have a legal responsibly to manage risks to mental health and well-being like they do any other health and safety risk.

Knowing where to start can feel overwhelming but getting started doesn’t have to be. Take action to improve the mental health of your team today.

Tips to help build a mentally healthy work site

Create a more positive and supportive work site

Establish awareness and support for workers experiencing mental health issues

Celebrate workers and their efforts

Take steps to improve role clarity and job satisfaction

If you have challenges on your work site related to psychosocial hazards, give us a call for advice. As a HazardCo member you can have a chat with the experienced health and safety Advisory Team for no extra cost.

Lithium batteries are common in everyday life and on the worksite, their lightweight, long life, interchangeability and quick charge benefits mean that they are now used in everything from laptops to power tools to EVs. But did you know that they pose a significant risk and need to be a part of your health and safety plan?

What’s the risk?

Lithium batteries of all sizes have the potential to overheat and catch fire. The fire is hotter, harder to put out and the smoke from these fires is incredibly toxic. Lithium batteries generally overheat if they get wet, damaged or are used with incorrect charging equipment.

Damaged batteries can explode at any time giving off flames that burn anywhere between 500 and 1000 degrees celsius. These fires are very difficult to extinguish as both water and CO2 will only suppress the fire, not extinguish it. Even if the fire has been suppressed it can still ignite again if the battery still contains energy to burn. Because of this, lithium batteries need to be properly cared for according to the manufacturer’s instructions to minimise the risk, aside from that, you need a plan in place in case of a fire.

Hot tip: The bigger the battery the bigger the risk

Ways to minimise the risk:

Safe lithium battery disposal

Never dispose of Lithium batteries in general rubbish as it can result in a fire in your bin or on the way to a transfer station, creating a risk to those transporting them. The manufacturer should be able to advise safe disposal or check out your local battery recycling centre.

Lithium batteries are going to continue playing a crucial role in our workplaces and lifestyles, so it’s necessary to recognize the potential hazards associated with them. By having awareness of these risks and good practices, we can work together to reduce the potential dangers, resulting in safer working environments where Lithium batteries are used.

If you have any questions, give the Hazardco team a call today!