Demolition machinery

Working with heavy machinery can be dangerous. Incorrect use or untrained operators can lead to serious injuries or worse.

Training and supervision

Machinery should only be used by workers who are:

- Trained and competent with the equipment they’re operating

- Supervised, especially if they’re new or unfamiliar with the task

- Provided with clear instructions, risk assessments and SWMS

Regularly assess operator competency through refresher training, observations and feedback. Keep training records and verify workers have the appropriate licenses.

Pre-Start Check – A quick routine that makes a big difference

Before using any machinery, complete a daily prestart check. These checks must be done by a trained and competent person.

Visual checks (before turning the machine on):

- Fluid and oil levels are good, and there are no leaks

- Battery is clean, charged and secured

- All safety guards and features are in place and undamaged

- Warning signs are in place and easy to read

- All clips, pins, and attachments are secure and not worn or damaged

- Hydraulic hoses are in good condition and lubricated

Stationary test (machine is on but not moving):

- Horn, reversing alarm and lights are working

- Pedals, and control panel are working properly

- Bucket and arms fully extend, retract and tilt smoothly

Moving test (short drive):

- Steering is responsive

- Brakes function correctly

Use the manufacturer’s pre-start checklist, or the HazardCo App Plant/Machinery Pre-start tool to guide your checks. Making sure to keep a record of your completed checks.

Quick Hitches, Safety Locks, and Exclusion Zones – Take the time to get it right

Quick hitches help you swap attachments fast – but can be dangerous if not properly secured.

Before operation:

- Confirm the attachment is the right fit and in good condition.

- Visually check all locking pins and safety devices are installed correctly.

- Set and mark exclusion zones and communicate these to all workers on-site

All quick hitches must clearly show:

- Model and serial number

- Manufacturer’s name

- Weight and max rated capacity

- Safe lifting capacity for each lifting point

Store spare locking pins with the machine, and only use attachments that match the correct pin size.

Cover any machinery risks and controls in your SWMS and share it with everyone on-site.

Don’t cut corners on safety

Missing a step like skipping a daily check or rushing an attachment change can have serious consequences.

Taking five minutes to do it right can prevent serious injuries and keep your sire running safely.

If you have any questions, get in touch with the HazardCo Team today

Digging into the ground might seem straightforward, but excavation work is actually one of the most dangerous parts of construction. That’s why it’s important to plan ahead and put the right safety measures in place to keep everyone safe on site.

Start with a solid plan

Before you get started, take some time to plan things out. Planning involves identifying the hazards, assessing the risks, and deciding suitable controls — all with input from the team. Every site is different, so take its unique features into account.

Watch out for these common excavation risks:

- Securing the area

Keep excavations fenced off with sturdy barriers that won’t give way if someone leans or falls against them. If you’re not actively working in or near the trench, cover it up or backfill it as soon as possible.

- Falls from height

If there’s a chance someone could fall from one level to another, it’s considered working at height. Make sure you have effective controls in place to prevent falls.

- Ground collapse

This is one of the biggest dangers. Don’t assume the ground will stay put. Use shoring, benching, or battering to prevent it from caving in.

- Safe ways in and out

Make sure workers have safe access at all times. Keep the bottom of the excavation clear so nothing blocks a quick exit in an emergency.

- Underground and overhead services

Always contact Before You Dig Australia. Know what’s under and above you — hidden services can be a major hazard if you hit them.

- Water in the trench

Never let workers operate in a trench that has water pooling in it unless you’ve got the right safety controls in place.

- Do you need to notify construction excavation work?

Some excavation work needs to be reported to WorkSafe Victoria before you begin. If that’s the case, you will need to notify at least three days before work starts.

Keeping yourself and your team safe is what matters most. Make sure you’re clear on your responsibilities when it comes to managing excavation risks.

Need a hand? The HazardCo App has helpful resources for site reviews and risk controls. And if you’ve got questions or need support, just reach out to the HazardCo team – we’re here to help.

When you’re able to get back on site after a flood or storm, here are the hazards, risks and control measures you should consider to help reduce the risk of injury and illness to yourself, your workers and others involved in the clean up and repair effort.

Some common hazards following a storm or flood:

- Electrical – Water damage, loss of power, damaged electrical installations

- Biological hazards and fauna – Contaminated floodwater and displaced fauna

- Asbestos – Damaged building materials that contain asbestos

- Slips, trips and falls – Uneven surfaces from storm/ floods

- Hazardous chemicals – Buried, moved or damaged hazardous chemical containers including corrosives, oils, pesticides

- Psychological stress – Remember to check on your team, the emotional impacts of a storm or flood can be overwhelming, particularly if they are dealing with personal damage

Risk Management

- Identify the hazards – What are the hazards on your site including any newly introduced hazards due to the storm or flood?

- Assess the level of risk – What is the likelihood of exposure to the hazard, and the consequences (what harm could be done)?

- Control the risk – Identify and implement suitable control measures and ensure the risk has been reduced to an acceptable level prior to undertaking related work.

- Review the control measures – Regularly assess how effective the controls are. It’s important to stop work and reassess if conditions change or if you have introduced any new hazards.

Safety tips when undertaking the cleanup and repair work

- Work out the order of the work to be done so that new risks are not introduced, e.g. if you move things in the wrong order is there a possibility of creating instability.

- Ensure surfaces are stable and access to areas with unstable floors are safe.

- Have a licensed electrical contractor check any electrical appliances or equipment you suspect has been submerged or damaged.

- Check in and under objects before attempting to move them as snakes, spiders and other undomesticated animals may be taking refuge from flood waters.

- Consider workers performing cleanup in teams/ pairs where possible.

- Wash your hands well before eating and drinking, after contact with mud, flood water and contaminated items and equipment.

- Make sure that workers have the correct personal protective equipment to prevent injuries such as cuts and scratches or infections from contaminated flood water.

- Check that your workers and contractors are not fatigued or potentially unfit to work, i.e due to mental health stressors.

- Agree on what situations workers should remove themselves from, where the risk cannot be reduced to an acceptable level. Some work may have to be delayed until water subsides and other factors.

- Ensure emergency procedures are discussed for the site with all workers.

Dust is a common hazard in the construction industry, especially during demolition or refurbishment. When buildings are demolished they can release materials that create hazardous dust (airborne contaminants) which can be hazardous to workers’ health. Understanding the risks will help you to identify how best to manage the risks.

Why is dust dangerous?

Exposure to hazardous dust can lead to serious health conditions, including:

- Silicosis – A lung disease caused by inhaling fine silica dust, common in concrete, brick, and stone materials.

- Lung Cancer – Prolonged exposure to certain airborne contaminants increases the risk.

- Asthma & COPD (Chronic Obstructive Pulmonary Disease) – Inhaling dust particles can trigger or worsen respiratory conditions.

- Skin & Eye Irritations – Dust exposure can cause infections and long-term discomfort.

Health and exposure monitoring

As a business, you have a duty to monitor your workers’ health when they’re exposed to certain substances and other hazardous materials. Regular health monitoring helps identify early signs of illness and ensures that the dust control measures in place are working effectively.

Health monitoring process should include:

- collection of workers’ demographic, medical and occupational histories

- records of workers’ exposure

- respiratory questionnaire and function tests

- in some cases, chest x-ray or other radiological procedure

It is important that you get your worker’s consent to monitor their health and engage them in this process.

Health monitoring should be carried out by a trained and competent person. They will also give recommendations based on the health monitoring results.

How to control dust exposure on-site

Controls to minimise the exposure to dust in the workplace could include:

- on-tool dust extraction systems – attach vacuum extraction directly to power tools

- water suppression – dampen materials to prevent dust from becoming airborne

- personal protective equipment (PPE) – ensure workers wear correctly fitted masks and protective gear

Making sure your workers have the right tools and information to complete the job safely includes training and understanding the risks involved, what to do if anything should go wrong, as well as the correct use, storage, and maintenance of PPE.

Other controls to consider are:

- limiting worker exposure – keep unnecessary personnel away from dusty areas

- task rotation – reduce the time any one worker spends in high-dust zones

- Dust containment – using sheeting or temporary screens to enclose the work to stop dust from escaping

Complete a SWMS for your demolition work through the HazardCo APP. This helps assess the risks and plan safe work processes. Involve your team so everyone can contribute and understand the plan.

Our team of health and safety experts are just a call away if you have any questions or would like to discuss further.

To put it simply, health and safety regulators (WorkSafe / SafeWork) work with you and your workers to keep you safe and healthy. Their main goal is to ensure that across Australia, businesses are safe and healthy environments. It’s important to know that not all visits are pre-arranged and inspectors are allowed to show up at any reasonable time, regardless of whether or not you’re there. So, what should you expect when they come a-knocking?

What does a site visit look like?

Typically a visit from WorkSafe/SafeWork follows the below process:

Step 1: Conversation

A friendly chat isn’t that scary, right? When the WorkSafe/SafeWork inspector first arrives, they’ll have a conversation. This discussion is a two-way street where they’ll be looking to learn about your business, what risks you’ve identified, the actions you’re completing to minimise them and answer any questions you may have. Ensure you use this opportunity to ask questions and seek clarification if anything doesn’t make sense.

Step 2: Observation

Following the chat, the inspector will usually take a walk around your worksite to have a look around. Sometimes its a general walk around, other times it may be focusing on a particular area or activity.

If the inspector sees anything concerning during the walkabout, they will discuss this with you further.

Step 3: Processes and Documentation

At this stage, the inspector might ask to see what kind of processes and safe practices you have. This could include anything from your risk assessments, worker’s licenses or training certificates, machine maintenance logs, to incident reports. The focus will be on whether your processes and records demonstrate good health and safety practices for your worksite, workers and business.

So what are inspectors allowed to do during the visit?

Inspectors have the right to:

- ask you, your employees or other people questions

- take photographs, recordings and measurements

- ask to see your documents, make copies or take the documents

- take items away with them for examination, testing or for use as evidence

What happens if an issue is found?

If the inspector does find an issue, you and the inspector will discuss what needs to be done to fix it. The three main outcomes issued by the inspector are an improvement notice, prohibition notice, or an infringement notice.

- Improvement notices – The most common type of notice which directs a person to address an identified health and safety risk in a specified time. The inspector will explain what was identified, how things need to change, and the timeframe in which it needs to be completed.

- Prohibition notices – Directs the business to stop doing a particular thing that involves a serious risk to health or safety. For example, stopping a specific activity or instructing you to stop using a dangerous piece of machinery. The notice will tell you what needs to be fixed.

- An infringement notice – This notice, or fine, is a penalty for breaking the law. Depending on your state or territory it can include an on-the-spot fine for breaching certain health and safety laws and may lead to prosecution.

Using HazardCo can cut the time you spend on health and safety admin in half and can guide you through what you need to do to keep your workers and your business safe.

Of course, if there are any questions or concerns, just call us at HazardCo for help on 1800 954 702.

When you have an incident on-site, whether it’s a near miss, an injury, or a work-related illness, it’s important to document an incident report.

Incident reports don’t need to be time-consuming, lengthy or use fancy health and safety terms, you just need to describe what happened in your own words so you have a record of the incident. You can use the incident report to help explain what happened to others, such as your direct team on-site, contractors, other Employers, or the Principal Contractor.

What is an incident report?

An incident report is the process of recording incidents on-site, such as near misses, injuries, illnesses and plant/property damage. It involves documenting all the facts (known so far) related to the incident.

Check out this blog on managing and reporting incidents at work to learn more about what is considered an incident and why it’s both important and helpful to report incidents.

How to complete an incident report

Example incident report: Hit body on object

Hitting your body on an object is a very common example of an incident. For this incident report example, we will assume someone on-site has hit their body on a door frame and injured their shoulder.

- Site Location

- 32 Dropsaw Lane, Cottesloe 6011

- People involved

- Joe Hazard (injured)

- Sam Small (witness)

- Larry Large (witness)

- Type of Incident

- Damage (equipment or property was damaged)

- Security/Theft (site accessed unexpectedly or something was stolen)

- Environment (Pollution or hazardous substance spill)

- Near Miss (Something occurred but there was no harm caused)

- Injury (Someone was physically hurt) ✅

- Illness (Work-related illness)

- Other (Something else happened)

- Other (Something else happened)

- Cause of Incident

- This is where you select from the the list of causes what the main reason for it occurring was – in this case, it’s person vs object.

- Treatment received

- First aid (performed on worksite)

- Medical Centre (Minor injury or illness) ✅

- Hospital (Major injury or illness)

- Unsure (I’m not sure what treatment was given)

- None (No treatment was required)

- Type of injury

- Select the category that best suits or select “other” to select your own, if you don’t know what type of injury happened you can also select “unknown”.

- Describe what happened – List the facts that are known so far about the incident such as :

- What job or activity was being performed at the time.

- What plant, equipment or tools were being used

- What went wrong

- What was the injury or damage (or the potential)

- What happened immediately after the incident

-

- Joe Hazard was carrying plywood through a doorway on-site when he hit his shoulder on the door frame. Joe felt immediate pain in his left shoulder and struggled to lift his arm above shoulder height. Joe informed Sam Small (Supervisor) immediately and agreed to go to the local medical centre for further assessment.

Pictures speak a thousand words so don’t forget that you can upload scene photos or relevant information in picture form at this step in the app, and if there’s something that you don’t want forgotten you can also create a task.

This is an example of a simple incident report, find out more about what good incident reporting looks like.

If you’re a HazardCo member, hit the Report an Incident button in the HazardCo App and follow the guided prompts to record the incident. Your membership includes 24/7 incident support, so if you need some extra help filling in the report, would like advice on if the incident is notifiable to the Regulator, or would just like to chat with an expert about how to communicate the incident to your team, we are here to help!

Remember, when you have an incident on-site, writing an incident report is just one action you need to take. Learn more about what to do when you have an incident on site.

Electricity is essential on construction sites, but if the risks are not managed properly, it can pose serious dangers to people and property. Proper controls must be in place wherever electricity is used to keep everyone safe.

Because we use electricity differently across a site there are different ways to help manage the risks.

Residual Current Devices (RCDs)

An RCD is an electrical safety device designed to immediately switch off the supply of electricity when electricity ‘leaking’ to earth is detected at harmful levels. RCDs offer high levels of personal protection from electric shock.

There are three types of RCD:

Fixed at the switchboard

- A switchboard RCD is the best option in most situations. It protects all the electrical wiring and appliances supplied from that circuit.

- An electrician must install a switchboard RCD.

Built into the powerpoint

- A socket-outlet RCD is built into a standard powerpoint to provide protection to equipment plugged into that powerpoint and, if required, downstream protection of other powerpoints.

- An electrician must install a socket-outlet RCD.

Portable

- A portable RCD can be moved from powerpoint to powerpoint as needed. There are a few different types of portable RCD:

- Some plug directly into a powerpoint. An appliance or extension lead then plugs into the portable RCD.

- Some are built into extension leads or individual appliance leads.

- Some are built into Portable socket-outlet assemblies (PSOAs).

- No electrician is needed – you can buy a portable RCD at a hardware shop or from an electrical equipment supplier, just make sure it is fit for purpose.

Testing

Keep you and your team safe while working around electricity by checking your RCD regularly. Across Australia, the testing frequency is based off the standard, AS/NZS 3012:2019 which sets the specific requirements for construction sites and states:

- Portable RCDs are to be push button tested daily before every use and an operating time test is to be performed by a competent person every 3 months.

- Fixed RCDs are to be push button tested 1 month and an operating time test is to be performed by a competent person every 12 months.

If an RCD is tested and found to be faulty it must be taken out of service immediately and replaced as soon as possible.

Leads and Cords

Leads and cords are easily damaged, particularly those connected to equipment that is often moved. To protect them:

- Use cable protectors, covers, non-conductive hooks, and ramps.

- Protect leads from sharp objects, footwear, doors, vehicles, liquids, grease, and heat.

- Arrange leads to prevent tripping hazards. Avoid running leads across aisles or passages.

- Elevate leads to keep them off the ground and ensure they are accessible without needing a ladder.

- Use insulated supports to relieve strain on plugs.

- Inspect leads for damage before use and have them tested and tagged regularly by a qualified person.

Testing and Tagging of leads and cords

Inspection, testing and tagging of electrical leads and cords on construction sites are required to be completed every 3 months* by a competent person.

Any lead or cord that is damaged or that fails testing is to be immediately taken out of use and removed offsite. If you cannot promptly remove it offsite, consider other means like attaching a durable out of service tag so as to warn workers not to use that piece of equipment.

Monitor and Review

When you complete your regular Site Reviews using the HazardCo App, make sure that you are checking RCD’s and all other electrical equipment are in good working condition and are regularly inspected and tested.

Further Information

If you have any questions in regards to this topic or need more support , reach out to HazardCo and speak to one of our expert Health and Safety Advisors. You can contact us on 1800 954 702.

*For Hire equipment, inspection is required prior to each hire and testing is carried out at least monthly. If hire equipment remains on the construction site then the frequency listed applies.

Health and safety is a core part of any business but incidents and injuries on the job can still happen. According to SafeWork Australia, in the construction industry alone there were 15,877 serious work-related injury claims between 2020 and 2021, and in the same period, there were 316 fatalities.

Construction and trades make up a fair portion of incidents and injuries at work. When you think about the cost of the time off, it adds up to a pretty staggered sum. As of 2020 the average compensation claim looks like:

- $24,628 in compensation paid

- 10 weeks of lost time per person

With numbers like this, we need to help you find a way to improve the health and safety culture so you can make sure it’s safe and profitable as well.

The signs of poor health and safety

If you’re concerned that your health and safety policies and procedures aren’t being followed or maybe not quite up to scratch, there are a number of things you can keep your eyes peeled for:

- Poor Incident Reporting

- Blame Culture

- Poor Communication

So, how do you get your crew on board?

When it comes down to it, creating a culture of site safety isn’t as easy as putting new procedures in place and calling it a job well done – it’s up to you to involve and motivate your crew to be proactive and take safety into their own hands. You need to make sure that your crew are on board and are taking the right steps to create a safety culture.

Some steps you can take include:

Communication

It seems like an obvious one but poor communication can really hinder your efforts to create a safety culture. Having regular honest and open communication with your crew about why you’re talking about all things safety is the best way to help them understand the importance.

The more transparent and clear you are, the more likely they will be to really take the new initiatives seriously. Make sure that your crew has easy access to your current health and safety guidelines so they can stay in the know about any changes.

Support your staff

Site safety isn’t just about incidents on your site, it’s also about being a supportive employer who ensures their people are feeling safe and secure when they come to work every day. Make sure that the physical health, mental health and even emotional health of your people is a factor for how you manage them. Those working in construction and trades like other sections of society are at risk of depression, stress, or anxiety as well.

If you are taking steps to improve your site safety culture, make sure you factor in both physical and mental health awareness in all that you do for your staff. By providing resources and establishing an environment where your crew feels respected and safe to open up and express themselves you’ll be able to create a support system where you can look after each other’s wellbeing and mental health.

Training

Ensuring that your crew are trained up on all the correct licenses, procedures and health and safety practices is a sure fire way to make sure that they are fully knowledgeable on correct procedures. With the right training in place, you can have confidence that they know how to safely and correctly perform their jobs.

Be a leader

We’ve all experienced bad leadership before, and that if they don’t care about something, it’s highly unlikely you will either. So, if your crew sees that you don’t take health and safety seriously, you’re out of luck getting them to foster a culture of site safety.

You need to walk the walk before you talk the talk. Demonstrate to your crew the importance of following health and safety standards by doing them yourself. They’re a whole lot more likely to follow your example than just take your word for it.

Reporting

You need to set the tone with your crew that reporting incidents isn’t something they need to feel anxious or uncomfortable about doing. Make it clear that they won’t get in any trouble for making a report but instead see it as a way of finding out what caused the accident or injury and what can be done to make sure it won’t happen again. By making proper reporting a core element of your crew’s job responsibilities it can become second nature to them.

Make it a team effort

Site safety impacts everyone, so it makes sense that your crew should have a hand in shaping their site’s culture. The more input they have, the more likely they are to follow precautions.

By having regular health and safety chats with your crew, you can give them the opportunity to voice their own safety concerns and opinions. By having open conversations and allowing input from your crew you’re giving them the ability to implement safety measures that affect their own jobs, ultimately making them more likely to follow processes and encourage others to do the same.

If you have any questions please reach out to the HazardCo team today

We’re going to run you through Respiratory Protective Equipment (RPE), which is a type of personal protective equipment (PPE) which protects people from inhaling substances that are hazardous to their health. These hazardous substances include airborne contaminants such as asbestos, hazardous chemicals and dust, fumes (such as welding fumes), and infectious substances, but you should keep in mind that RPE should also be worn to protect the wearer from low levels of oxygen such as working in confined spaces.

But, before you even get started with RPE, make sure you have other practical control measures in place such as local exhaust ventilation to minimise or eliminate contaminants in the air. Also, keep an eye on your team’s health and workplace conditions to ensure that they aren’t injured or made sick by their work.

We’ve gone ahead and put together a quick guide of factors to consider when providing your workers with RPE.

Types of RPE

Respirators that use filters remove contaminants from the air which the wearer will be breathing. Disposable respirators (often called dust masks) are good for short-term or one-off use and protect the wearer from harmful particles such as dust, fumes, fibres, and biological hazards such as bacteria or viruses.

Powered air purifying respirators (PAPRs) consist of headgear and fan assembly that take contaminated air, filters and removes a sufficient portion of these hazards, and then delivers the clean air to the user. These are also known as positive pressure masks, blower units, or blowers.

Supplied air respirators provide a supply of clean air to the wearer from a source such as an air compressor or cylinder. It’s important to note that the air supply needs to be checked regularly to make sure that it is safe to use.

Using RPE

It’s important for your workers to visually check their RPE for signs of damage before each use so that they can let you know if there are any issues, including whether it needs to be cleaned or decontaminated.

Make sure your team stays safe by keeping their RPE on while working in the hazardous area. Removing it for even a short period of time could be a risk to their health.

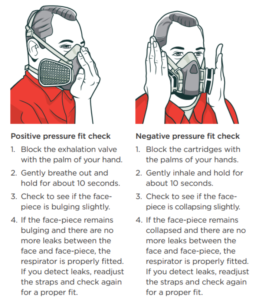

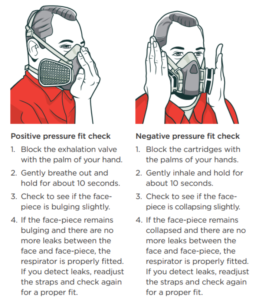

If your workers are using RPE that requires a tight fit, make sure that they are checking it properly before entering the hazardous area. There are two fit checks which they need to do:

Keep in mind that if your worker’s safety glasses fog up while they are wearing a half-face respirator, this is a sign that there is a leak at the top of the respirator.

Life Shavers: shaving your beard could save your life

When your workers are wearing respiratory protective equipment at work, they should be clean shaven to ensure it is forming a seal and protecting them from breathing in hazardous materials. Even a small amount of stubble can prevent RPE from sealing correctly which means your workers will still be inhaling harmful materials which may cause health concerns. A clean shave goes hand in hand with the correct RPE for the job.

It’s your responsibility to monitor your workers’ health. Make sure that you are completing regular Site Reviews on the HazardCo App, as this will help you to identify potential hazards and put effective plans in place.

HazardCo understands that on-site first aid is about more than just sending someone on a course every few years. As an employer or principal contractor on-site, you have a legal and moral obligation to make sure your team has access to first aid equipment and facilities, as well as access to trained first aiders.

To determine the necessary level for your workplace, assess the site by considering:

- The type of work being done

- Identified hazards

- Site size and location

- Number of people on-site and any vulnerable workers

- Conduct a first aid risk assessment to identify facilities, equipment, and training..

Don’t forget to involve your workers in the process and if you are working with multiple trades, or are the principal contractor, you should share information and work together cooperatively.

First Aid Kits

Having a first aid kit on a construction site is essential to quickly address injuries and medical emergencies. Great kits can be sourced from many places – a basic kit should include equipment t to tend to:

- cuts, scratches, punctures, grazes, and splinters

- soft tissue sprains and strains

- minor burns

- broken bones

- eye injuries

- shock

Basic first aid kits are not always enough given the nature of construction work and increased risk of eye injury, cuts, falls etc, so you’ll need to consider what other equipment to add e.g. eye pads, eyewash, additional dressings and bandages.

Include your team and see if they think your first aid kit is sufficient for the site hazards and team size… and make sure they know who the trained first aider is and where the first aid kit is kept! It helps if your first aid kit is clearly labeled and is made from a material that can protect the contents from dust, moisture and contamination.

Lastly, assign someone to be in charge of replenishing the kit. Make sure this happens regularly and keep a list of what’s supposed to be in the kit to make topping it up easier. At the same time, check training is up to date for your first aiders, and if your team size has changed, whether you still have enough team members trained in first aid.

Keeping first aid up to date is the right thing to do by your team, so make sure you’ve got things covered and that you’re all prepared if any sort of injury takes place.

If you have any questions please contact the HazardCo team today.

Looking for something in particular?

Summer’s here. Are you ready for the heat?

Longer days and sunshine make it feel like the perfect time to crack into work. But while summer brings good vibes, it also brings its own set of ri...

Kick off the New Year safely on site

The holidays are done and dusted, and it’s time to ease back into work. Reopening your site safely is just as important as shutting it down properly and t...

The Christmas break is nearly here. You're probably counting down the days until you can relax and spend some proper time with the family and friends.

But before you lock up for the holiday...

We’ve heard all sorts of myths and misconceptions when it comes to health and safety. We’re here to debunk some of the more common ones we hear.

H&S admin takes too long on-site...

MSDs (Musculoskeletal Disorders) are the most common type of work-related injury in Australia. In fact, over half of all serious workers’ compensation claims in construction back in 2024 were ...

Health in the construction industry is often overlooked, but it has a huge impact on workers and businesses. Physical and mental health issues are among the biggest reasons for time off work a...

Got lone workers on your team? Here’s what you need to know

If someone on your team is working by themselves without other people around and without direct supervision, they’re likely conside...

Take the Hassle Out of Toolbox Meetings.

Toolbox meetings don’t need to be a paperwork mission. With the HazardCo App, you can run quick, focused chats straight from your phone. No prep, no p...

Get your team scanning in and out – it’s a no-brainer!

We get it, health and safety chats aren’t always the most exciting. But they are the most important. When everyone on-site takes part,...

Working with heavy machinery and managing traffic on-site can be risky. But with the right checks and planning, we can keep everyone safe.

Daily machinery checks

Before starting work each da...

Demolition machinery

Working with heavy machinery can be dangerous. Incorrect use or untrained operators can lead to serious injuries or worse.

Training and supervision

Machinery sho...

Digging into the ground might seem straightforward, but excavation work is actually one of the most dangerous parts of construction. That’s why it’s important to plan ahead and put the right s...