HazardCo understands that on-site first aid is about more than just sending someone on a course every few years. As an employer or contractor on-site, you have a legal and moral obligation to make sure your team has access to first aid equipment and facilities, as well as access to trained first aiders.

To determine the necessary level of first aid for your workplace, assess the site by considering:

Don’t forget to involve your workers in the process, and if you are working with multiple trades, or are the main contractor, you should share information and work together cooperatively.

Having a kit on a construction site is essential to quickly address injuries and medical emergencies. Great first aid kits can be sourced from many places – a basic kit should at least include equipment to manage:

Basic first aid kits are not always enough given the nature of construction work and increased risk of eye injury, cuts, falls etc, so you’ll need to consider what other equipment to add e.g. eye pads, eyewash, additional dressings and bandages.

Include your team and see if they think your first aid kit is sufficient for the sites hazards and team size. Make sure they know who the trained first aider is and where the first aid kit is kept! Make sure your first aid kit is clearly labeled and is made from a material that can protect the contents from dust, moisture and contamination.

Lastly, assign someone to be in charge of replenishing the kit. Make sure this happens regularly and keep a list of what’s supposed to be in the kit to make topping it up easier. At the same time, check training is up to date for your first aiders, and if your team size has changed, whether you still have enough team members trained in first aid.

Keeping first aid up to date is the right thing to do by your team, so make sure you’ve got things covered and that you’re all prepared if any sort of injury takes place.

If you have any questions please get in touch with the HazardCo Team

Maintaining clean amenities is just as important as keeping your site nice and tidy. Employers have a duty to provide adequate workplace amenities/facilities, including toilets, that are in good working order, clean, safe and accessible.

When planning amenities on your site, consult with your workers to understand what will be needed. Getting them involved will give you the opportunity to provide information, training and instruction on things like keeping the site amenities clean and reporting any problems.

More often than not portable toilets are not maintained in a safe or hygienic way. Employers must make sure that toilets are cleaned and serviced regularly, making sure they are safe to use, just like any other on-site machinery.

Toilets should also:

Don’t forget, the toilet should be easy to access in all weather conditions and be placed on stable, flat ground to ensure it can operate properly.

Clean drinking water must be supplied to workers by installing site water taps as early as possible. If the mains have not been connected, provide workers with drinking water in containers, coolers or flasks.

Workers should have a clean and sheltered area for meals and rest breaks. A garage or a similar sheltered area can be used or a vehicle cab if there is no other reasonably practicable option, so long as basic requirements for worker rest can be met.

Not meeting these requirements can lead to a risk of infection, disease, psychosocial harm or infringements/enforcement from the Regulator. Planning is key to ensuring you and your team have what you need in place from start to finish.

As always, if you have any questions please give our team a call on 0800 555 339 or contact us.

Tools, vehicles, and heavy equipment all create vibrations that can affect your body. This is a normal part of any tradie’s day, whether you’re picking up power tools or jumping in the truck. It’s so common that many don’t realize the potential harm these vibrations can cause. However, it’s something you should start thinking about and being aware of.

Vibrations are a natural part of working on any construction site but they do create a risk to you and your workers. Repeatedly using vibrating hand and power tools, or being around vibrating vehicles and machines can lead to serious and lasting harm to your blood vessels, nerves, and joints. Many of the most commonly used items give off some form of vibration. Here are the most common ways tradies are exposed to vibrations:

While these are the most common forms of exposure, the below should also be considered as they increase the risk of overexposure to vibrations:

We understand that for many tradies, working with vibrations is a natural and unavoidable part of the job. With that in mind, there are a few warning signs and symptoms of overexposure to keep an eye out for:

If you are continually exposed to vibrations especially in your hands and arms you can develop hand-arm vibration syndrome (HAVS) or carpal tunnel syndrome (CTS)

It is up to everyone on-site to look out for each other. Consultation with your team should take place to make sure an environment can be created where excessive exposure to vibrations are eliminated when possible or minimised when they can’t be avoided.

Below are simple yet effective ways to either eliminate or minimise the effects.

Above all else, be aware that vibrations can be extremely harmful, especially when you’re exposed for lengthy periods of time.

Your best tool for minimising the effects of vibrations is to start a conversation with your boss, or your team, and put steps in place to look out for each other and your equipment.

Worksafe resources: https://www.worksafe.govt.nz/topic-and-industry/vibration/

Respiratory Protection Equipment (RPE) is essential gear for protecting you from inhaling hazardous substances. In this blog, we’ll explore the important role of RPE, whether you are dealing with airborne contaminants like asbestos, fumes, or dust, RPE is an essential protective equipment (PPE) that makes sure you can breathe safely. Join us as we deep dive into the different types of RPE, their applications, and how they can protect you from potential health risks.

Before you even get started with RPE, make sure you have other practical control measures in place first; such as local exhaust ventilation or direct dust-extracted tools with a vacuum catchment to get rid of the majority of contaminants in the air. You should also be keeping an eye on your team’s health and workplace conditions to ensure that, over time, they aren’t being made sick or getting injured by their work.

Remember, there is no such thing as a healthy dust, even if you are outside!

We’ve gone ahead and put together a quick guide of factors to consider when providing your workers with RPE.

Dust masks are basically the bottom of the list of ways to protect yourself, we would not recommend using these as they are mostly ineffective at creating a seal between you and the contaminants.

Respirators use replaceable filters to remove contaminants to clean the air for the wearer. They come in half-face and full-face versions. The cartridge filters are specific to certain types of contaminants, ask your manufacturer exactly which cartridge you should be using for the respirator you have and the contaminants you will be facing.

Remember if you have stubble or any facial hair you may not be getting the seal and the protection you think you are! So if you love your beard as much as your lungs read on to find out what you can do.

Powered air purifying respirators (PAPRs)

Are made up of headgear and fan assembly that take contaminated air, filters it, and then delivers the clean air to the user. These are also known as positive pressure systems. These not only keep you nice and cool, but offer the highest protection there is for people who have facial hair. Something to note with these is that the visors and headset can be impact rated if you need it, and don’t fog up because of the airflow

Supplied air respirators

Provide a supply of clean air to the wearer from a source such as an air compressor or cylinder. It’s important to note that the air supply needs to be checked regularly to make sure that it is safe to use – just think about what you see coming out of your air compressor when you release the valve under the air tank! The user must also be trained in how to use the system. If using these RPE’s you need to notify WorkSafe.

It’s important for your workers to visually check their RPE for signs of damage before each use to identify any issues, including whether it needs to be cleaned or decontaminated.

Make sure your team keep their RPE on while working in the hazardous area. Removing it for even a short period of time is a risk to their health.

Did you know that they come in different sizes? One size does not fit all!

If your workers are using RPE then make sure they are fit tested, this way you will know who needs what size, otherwise it may not work and give the protection your workers need.

The manufacturer of the RPE can tell you who can do this testing.

There are two checks which you need to do each time you use and RPE:

1 – check for damage visually to the sealing surfaces and straps

2 – check the valves are functioning correctly like WorkSafe images below

Image Source: Worksafe New Zealand

Keep in mind that if your worker’s safety glasses fog up while they are wearing a half-face respirator, this is a sign that there is a leak at the top of the respirator which means they are not getting full protection.

When your workers are wearing respiratory protective equipment at work, they must be clean shaven to ensure it is forming a seal and protecting them from breathing in hazardous materials. Even a small amount of stubble can prevent RPE from sealing correctly which means your workers will still be inhaling harmful materials which may cause health concerns. A clean shave goes hand in hand with the correct RPE for the job.

It’s your legal responsibility to monitor your workers’ health. Make sure that you are completing regular Site Reviews on the HazardCo App, as this will help you to identify potential hazards and put effective plans in place. Your HazardCo Support Team is available throughout the day to guide you through this – call 0800 555 339 to talk it over.

Image Source: Worksafe

A musculoskeletal disorder is any pain felt in the muscles, bones, ligaments, tendons, blood vessels or nerves. You can feel this pain in just one area of the body, or throughout your whole body. The pain can range from mild to severe enough to interfere with your day-to-day life.

Trades workers have had the highest number of claims by occupation. According to ACC data Ligament, tendon and muscle injuries (also known as Musculoskeletal Disorders or MSDs) made up 65% of all claims. It is the most common type of injury where someone requires more than a week off work, a whopping 1,590 injured construction worker incidents were logged with WorkSafe between Jun22 and May23.

The residential construction industry is currently booming and subsequently the ACC claim numbers and payout costs for strains and sprains are also increasing. There are numerous factors which increase the risk of musculoskeletal injuries, these include time pressure, ageing workforces and unsafe lifting techniques.

We need to change the mindsets of workers thinking that “pain and injury is unavoidable” and make our younger workforce understand the combined impacts of repeated injuries – something that more experienced builders know very well.

It is well known that there are a range of factors that contribute to MSDs. It’s not just about a single factor such as the lifting technique (although for industries such as scaffolding and roofing, lifting and handling techniques are an important factor).

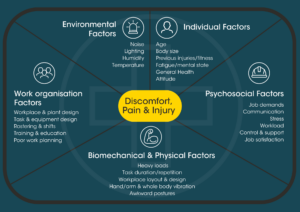

The research firmly points to five groups of factors we need to tackle when addressing MSDs in construction as shown in the diagram below these are work organisation, environmental, individual, psychological, biomechanical and physical factors:

It may not surprise you that physical factors often take most of the blame as their connection is easy to understand, measure and observe. There are also proven strategies to overcome physical factors such as machinery, equipment and task modifications.

Understanding how these factors can combine and influence each other to cause problems will be crucial. Working together and combining solutions to them in your approach is where the construction industry will get the most benefit.

The most common solutions for some of the above risk factors are:

We dive deeper into what treatment might look like, prevention tips, and the unseen costs associated with MSD in the blogs below:

Musculoskeletal what treatments might look like and prevention tips

5 things you can do to tackle musculoskeletal problems MSDs in your business

Musculoskeletal the hidden costs to workers lives and businesses

If you need anymore information get in touch with the HazardCo team.

Worksites tend to be filled with constant noise from tools and machinery. Work-related hearing loss is a real threat for many who spend the majority of their working lives on-site. While noise often means things are getting done, there is a downside to it. Hazardous noise can affect a worker’s physical and mental wellbeing including hearing loss, stress, and lower productivity. So to help you protect your hearing, here are a few helpful tips to manage noise.

Understanding what makes noise on-site, how it impacts people and different areas on site is critical. Ask yourself and your workers:

Once you understand the answers to the above, you can start putting plans and checks in place to monitor noise on-site.

Be sure to review the plan throughout the project, as different stages will create varying levels of noise.

The easiest way to decrease the effect of excessive noise on your site is to eliminate the source of noise completely. But, chances are this isn’t possible on a busy site.

The next best thing is to reduce noise.

A couple of easy ways to do this include:

Isolation involves creating a dedicated space for ‘noisy work’. This could be an enclosed room or area of site where all noisy work and machinery is used. This helps manage the noise by blocking the path of noise and reducing the levels that reach your team.

Having a good understanding of how machinery and tools operate can help modify processes to reduce noise at the source. Engineering controls can include choosing attachments or parts that are noise reducing, or changing the way machinery and tools are used.

Perfect for when you are running a large generator or a dedicated workspace, acoustic enclosures help to trap the noise within its barriers.

Setting up an acoustic enclosure that has 2 or 3 barriers/ walls can reduce noise.

What makes a quality acoustic enclosure:

With noise comes vibrations. These vibrations can be just as harmful as the noise itself.

Here are a few strategies to help decrease vibrations when using machines or power tools:

It’s not possible to escape noise on-site, however we can manage noise and put steps in place to help reduce the effect that it has on us while we’re working.

If you have any questions don’t forget to reach out to the team!

It’s no secret being a tradie is a very physically and mentally demanding job. With long workdays and weeks placing the body under intense physical and mental strain.

Worker fatigue is one of the biggest hazards on-site. Fatigue can come in many different forms and be caused by a number of different factors. While fatigue may not be avoidable in today’s busy cycle, it is important we recognise the signs of fatigue and steps to reduce it.

Because at the end of the day, a tired worker is a dangerous worker.

When you’re fatigued, you’re less alert and aware of your environment. This can lead to increased risk of errors resulting in injuries or incidents on-site.

On-site it’s both the individuals and the employers responsibility to recognise and reduce worker fatigue.

As an employer on-site you are required to provide a safe working environment, and reducing fatigue is included. Here are a few strategies for ensuring everyone stays fresh.

Workers are also personally responsible for turning up every day in the best mental and physical conditions possible, so that what they do on-site doesn’t affect the health and safety of others. Workers should:

Our bodies operate differently during the cooler and warmer months. During winter, fatigue levels tend to increase. With the colder temperatures, longer nights and reduced sunlight, our bodies naturally tend to shut down earlier in the day. During summer, we benefit a lot from longer days and more sunlight, however we need to consider fatigue due to hot weather and maintaining our hydration levels.

Fatigue is something that we all face in our busy work lives and is often unavoidable. However, it is critical we can recognise the signs of fatigue in ourselves or someone on-site.

By being able to recognise the signs and take the necessary steps to help is the best way to reduce fatigue-related problems on-site. If you have any questions don’t forget to reach out to the HazardCo team

Everyone should make an effort to stay healthy… When it comes to construction and the health of your workers, you are likely often working in loud or dusty environments, with airborne contaminants (e.g. silica or asbestos dust). In these instances, there is a legal responsibility to monitor your worker’s health. You need to complete specific health checks to monitor the impacts on your workers health while working in these conditions.

As an employer, health monitoring is something you should provide for your workers. It is a proactive way of ensuring your workers aren’t at risk in the workplace.

It is not an alternative to effective hazard control measures, rather, it helps you understand the effectiveness of your controls being used on-site.

If a worker’s health is being affected by exposure to construction-related health risks, it’s best to find out as early as possible to prevent any further harm from occurring. It’s intended to detect the early signs of ill health or disease (e.g. silicosis, asbestosis, mesothelioma, noise-induced hearing loss) and helps you monitor and protect your workers from exposure to construction-related health risks.

Health monitoring does not include general wellbeing checks or programmes, since things like cholesterol checks and healthy living programs aren’t specific to construction work.

You’ll need a registered medical practitioner with experience in health monitoring to perform, or supervise the medical tests. To assist your health monitoring efforts, HazardCo has partnered with Habit Health who provide medical checks nationwide. They’re experienced in health monitoring for the construction industry.

Remember, like all on-site health and safety, prevention is key. To ensure you’re meeting your legal requirements when it comes to health monitoring, get on-site with the HazardCo App, and complete an updated Site Review today. This will help you identify your hazards and put effective controls in place alongside health monitoring. Your HazardCo Advisory Team is available throughout the day to guide you through this – call 0800 555 339 to talk it over.

Asbestos related diseases is New Zealand’s number one work-related killer. Approximately 220 people die each year from preventable asbestos-related disease.

We’d like to give you some basic information on the dangers of asbestos, where it can be found and what you can do to avoid it.

There are two types of asbestos:

Inhaling asbestos fibres can cause a range of irreversible damage and diseases.

One of the most common asbestos related diseases is asbestosis. This causes severe scarring of the inner lung tissue. People usually have pain and severe difficulty breathing. Although this isn’t directly fatal in itself, it can lead to respiratory or heart failure.

Damage from asbestos may occur in as little as five years, or take as long as 40-50 years after exposure for symptoms to appear. Unfortunately, many people do not realise they have been exposed until it’s too late.

It is vital you don’t attempt to remove asbestos yourself, unless you are trained, certified where required, and fully competent – we cannot stress the importance of this enough!

If you’re planning to renovate or partially demolish a building, have a survey done first to identify if Asbestos Containing Material is present. If it is, contact your local asbestos removalist.

Any building constructed up until the year 2000 has a high probability of containing asbestos. View the posters created by WorkSafe on locations where Asbestos can be found on industrial and residential buildings. It is useful to familierise yourself and your workers with the areas relevant to your work. If it is not expected that asbestos would be present and you see unidentified asbestos while working, stop work immediately and arrange for an assessment of the Asbestos Containing Material (ACM) to be carried out.

Yes, there is. Disposal must meet strict guidelines. Bagging and wrapping asbestos pieces is essential in any sort of removal – and dumping asbestos-containing materials can only be done in authorised locations. It is important to check with your local council for specific disposal locations and requirements. Wherever possible, leave this to the asbestos specialists.

Removal of ACM greater than 10m² can only be performed by a licensed removalist. Clearance certificates are documented records of the removal and correct disposal. Keep these records on-hand with the other site documentation.

Recognition means everything when it comes to asbestos, signage on-site, equipping your team with knowledge of asbestos dangers, using the HazardCo App to assess risks, and educating your workers could be the difference between life and death.

For additional education and training on Asbestos we have partnered with two training providers, Safety N Action and BeSafe which both provide Asbestos courses. Check out your HazardCo’s Perks and Partners page for further information. There is a course available for whatever your asbestos needs.

What’s more, as a HazardCo customer with a current membership, you’ll get a 10% discount on any courses you undertake through these partners. Just advise them you are a HazardCo customer upon booking.

Remember to also undertake health monitoring for any workers who work with airborne contaminants (such as asbestos or silica dust). See Habit Health a national health monitoring provider – and again, as a HazardCo customer you receive a 10% discount on any services engaged.

HazardCo’s Advisory Team can help with any asbestos questions or other health and safety matters – give us a call on 0800 555 339.

Musculoskeletal disorders account for 27% of work-related ill-health in NZ

The musculoskeletal system is made up of the bones, muscles, tendons, ligaments, and cartilage of the human body. Maintaining good musculoskeletal health through prevention and early treatment can make for a long healthy career if you work in the construction industry.

Common injuries for construction workers can range from sprains, strains, and contusions (bruising) which can be caused by heavy lifting, repetitive movement, poor body posture, forcefulness or muscle effort, or the vibrations from continuous use of hand tools. Symptoms of a workplace injury can range from any kind of pain and discomfort located in and around the neck, shoulders, wrists, back, and knees.

When should I seek help if I suspect an injury?

As soon as you detect any pain or discomfort, inform your employer. It may mean adjusting your work for the day so as not to worsen the pain. You can seek medical treatment from a Habit Health physiotherapist if the pain or discomfort is preventing you from working or if you have any concerns. These health experts specialise in a range of areas and can tend to your unique needs before your injury gets worse.

How can physiotherapy help?

Provide support to get back on the tools quicker after injury. They can also assist with creating a return to work process, so employers know if and when workers will return to work. Including working with you to understand what work can be done, whilst you return to full mobility.

Musculoskeletal physiotherapy aims to help the patient recover from their condition more quickly through regular treatment sessions and to develop coping strategies to aid the patient during the recovery process and prevent secondary problems from occurring. This is achieved by manual therapy, education, exercise rehabilitation, and finding alternative ways to accomplish your goals and live your best life. The ultimate goal of your unique treatment plan is to bring your body function back to optimal so you can continue carrying out duties on-site and the activities you love in your personal time.

What can I do to prevent injury?

Prevention and early intervention are key to maintaining a healthy musculoskeletal system so you can carry out your day-to-day duties on-site as well as personal activities you love to do in your own time. Ensure you keep fit and healthy; regular exercise, a good diet, and sleep can assist in keeping your body ready to take on work and recover faster.

Try these simple exercises to help you warm up before you start your shift and continue throughout the day.

Habit Health’s Early Intervention Physiotherapy program

The RESOLVE Early Intervention Physiotherapy Program provides proactive support for your team, helping them get on top of pain, discomfort, or minor injuries quickly.

The program enables your employees to access a physiotherapist quickly to treat musculoskeletal issues. Early intervention can improve your employee’s health and well-being and help them to return to full fitness sooner. It can also reduce workplace costs resulting from pain, discomfort, or injury, and related absenteeism.